Application

In the 1960's, when shear testers for powders and bulk solids, especially the Jenike Shear Tester, were introduced, they were intended to be used first of all for silo design.

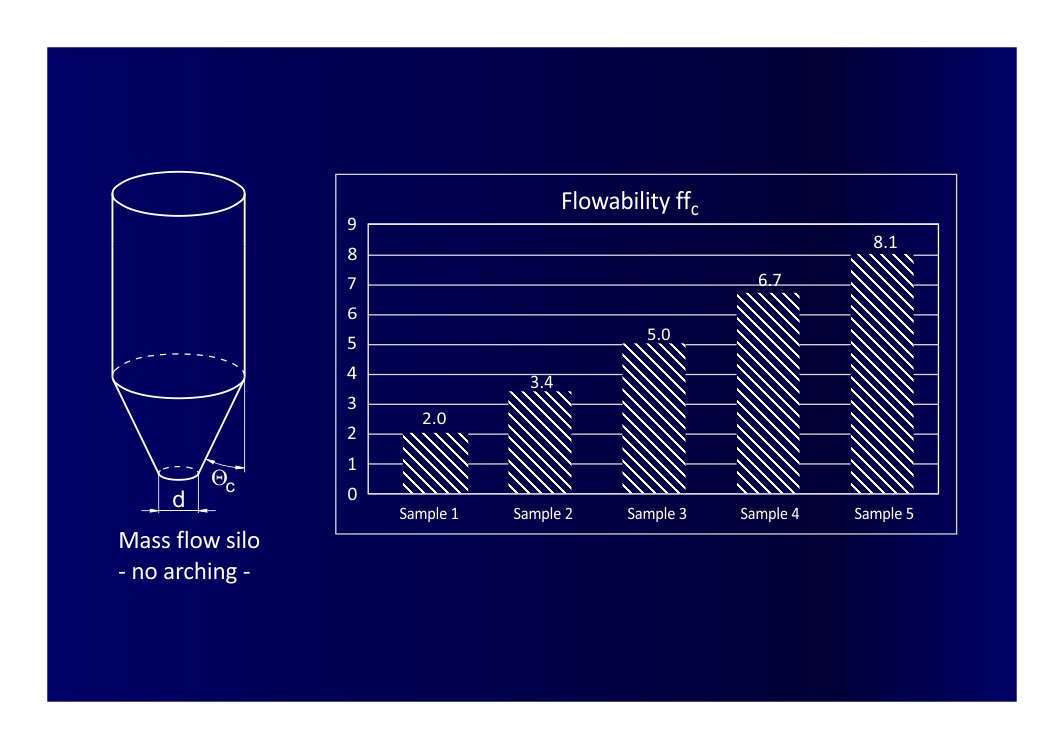

For silo design mechanical properties of the bulk solid have to be known which characterize the flow behavior sufficiently accurate. Only on the basis of safe and reliable data it one can predicted, for example, the minimum size of a hopper outlet required to avoid arching.

Due to easier operation, automatic test procedures and good reproducibility, our Ring Shear Testers have broadened the range of application of shear testers. Thus, many of our Ring Shear Testers are used in the context of flowability measurements and product optimization.