Example: Yield locus test with RST-CONTROL 95

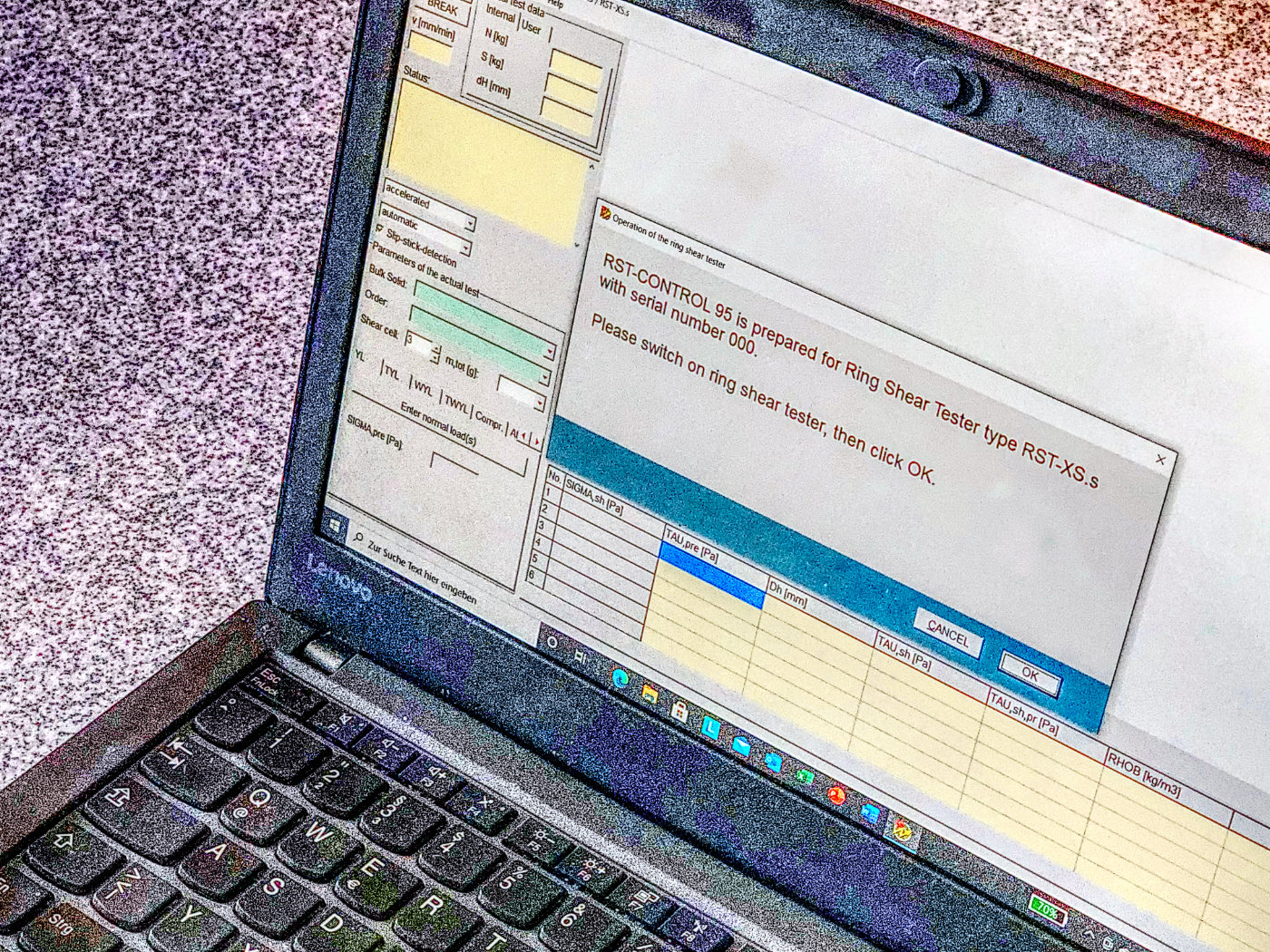

After starting the program,

RST-CONTROL 95 shows the evaluation window (picture below). Here,

the different measurements (yield loci, wall friction tests, time

consolidation, ...) can be viewed, edited and exported as

graphics. If several yield loci of the same product were measured

at different stresses, graphs of bulk density, unconfined yield

strength, or internal friction versus consolidation stress can be

plotted in diagrams.

After starting the program,

RST-CONTROL 95 shows the evaluation window (picture below). Here,

the different measurements (yield loci, wall friction tests, time

consolidation, ...) can be viewed, edited and exported as

graphics. If several yield loci of the same product were measured

at different stresses, graphs of bulk density, unconfined yield

strength, or internal friction versus consolidation stress can be

plotted in diagrams.

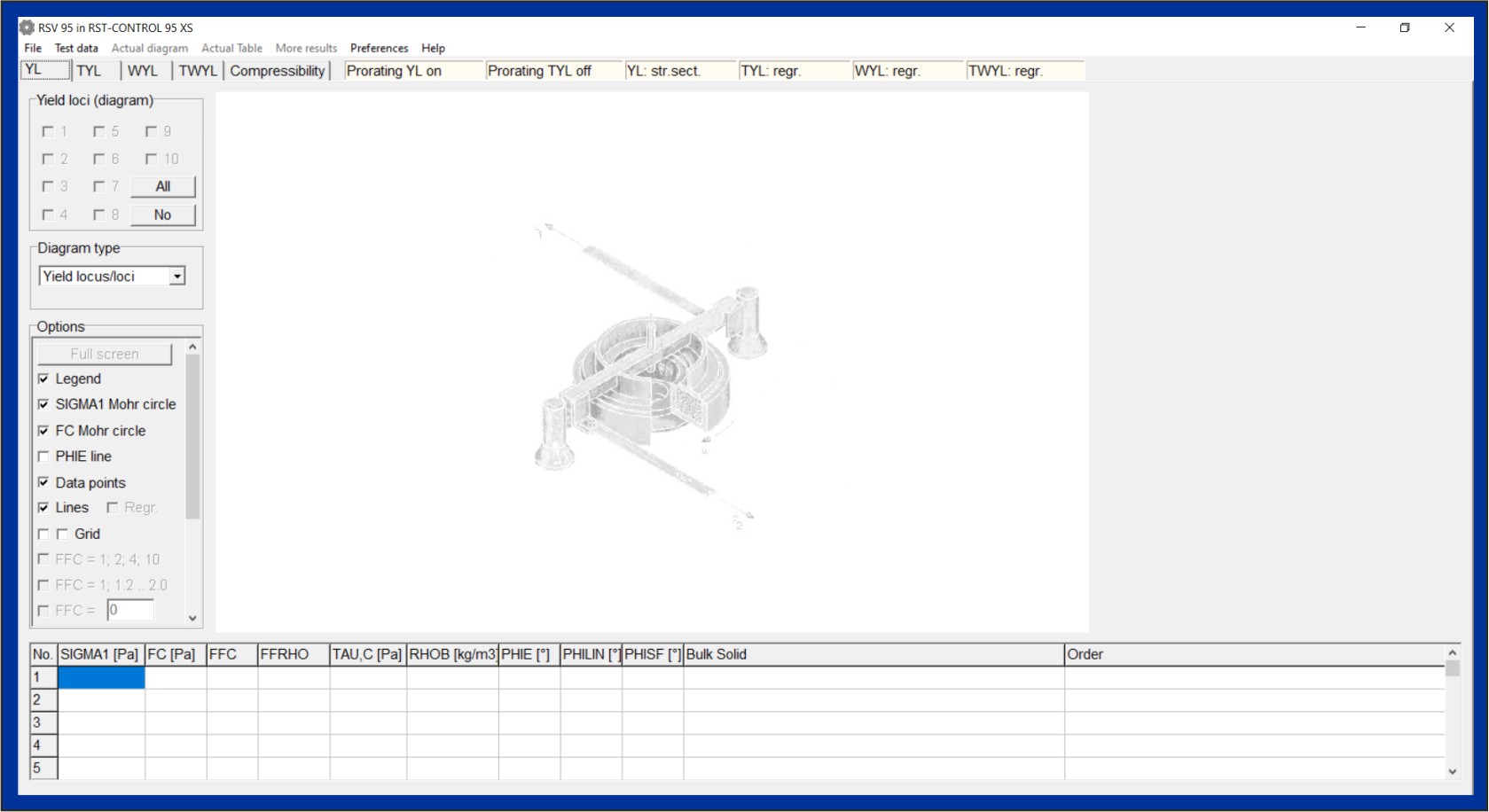

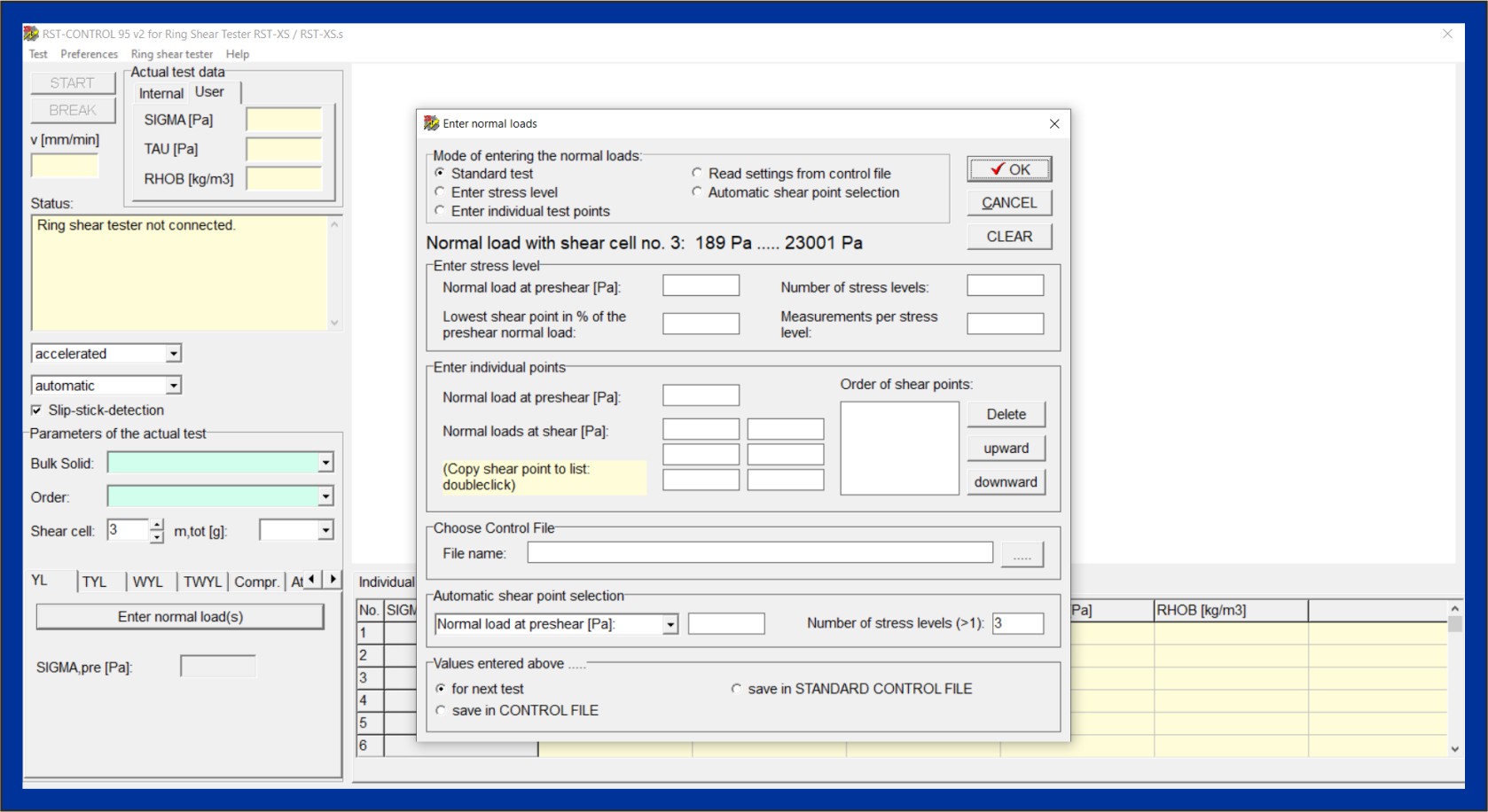

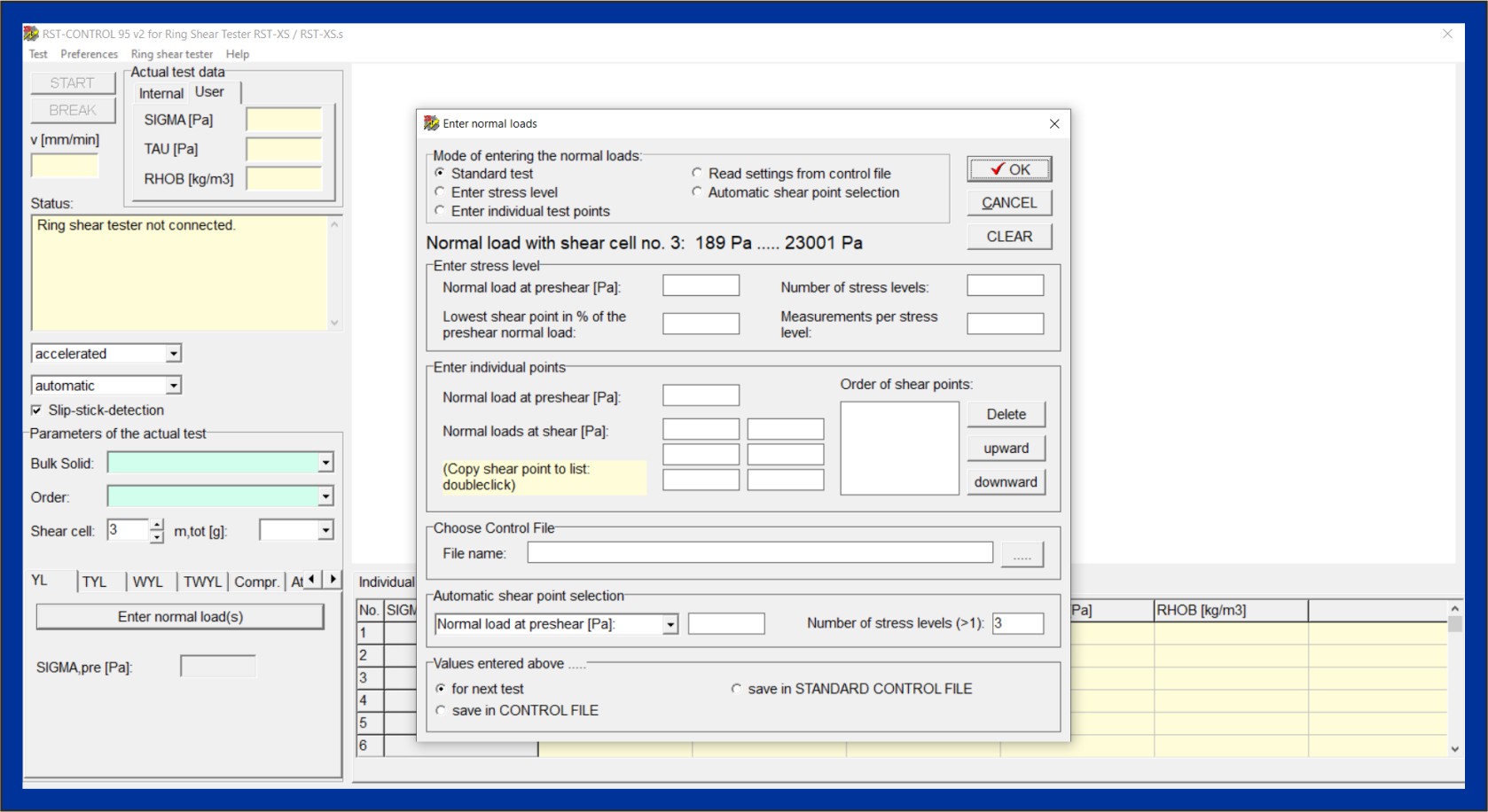

From the evaluation window you reach the measuring window

(RST-CONTROL 95 window, see figure below). In the lower left area

of the window, select the type of measurement, e.g. YL = yield

locus, or WYL = wall yield locus and select the number of the

shear cell that shall be used for the test. For entering the

normal stresses of the test points are entered in a window. On the

image the window for entering the normal stresses for a yield

locus test is opened. Depending on the requirements, a standard

test can be selected here, or previously created test procedures

(CONTROL files) can be opened, or individual test points can be

specified.

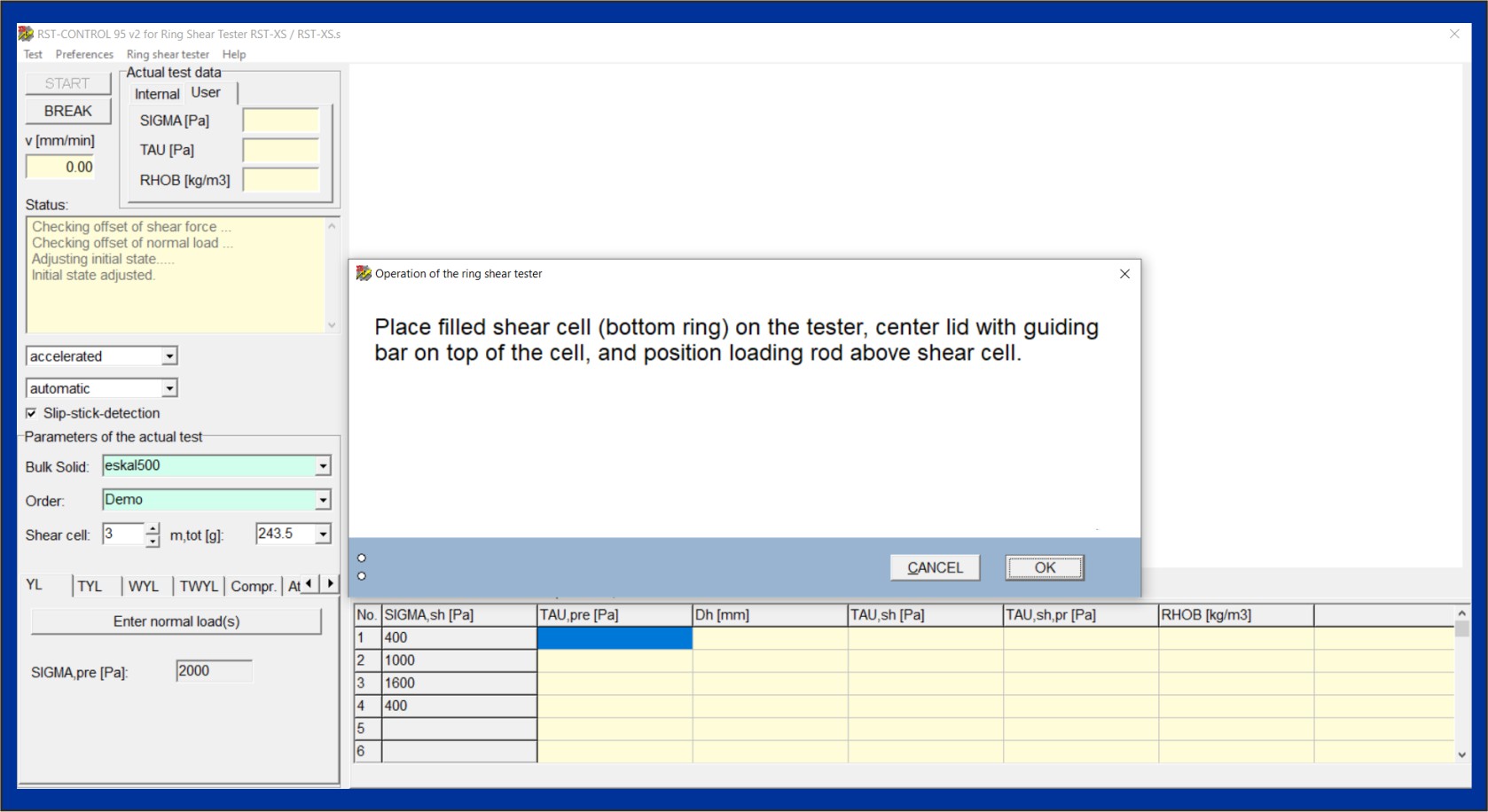

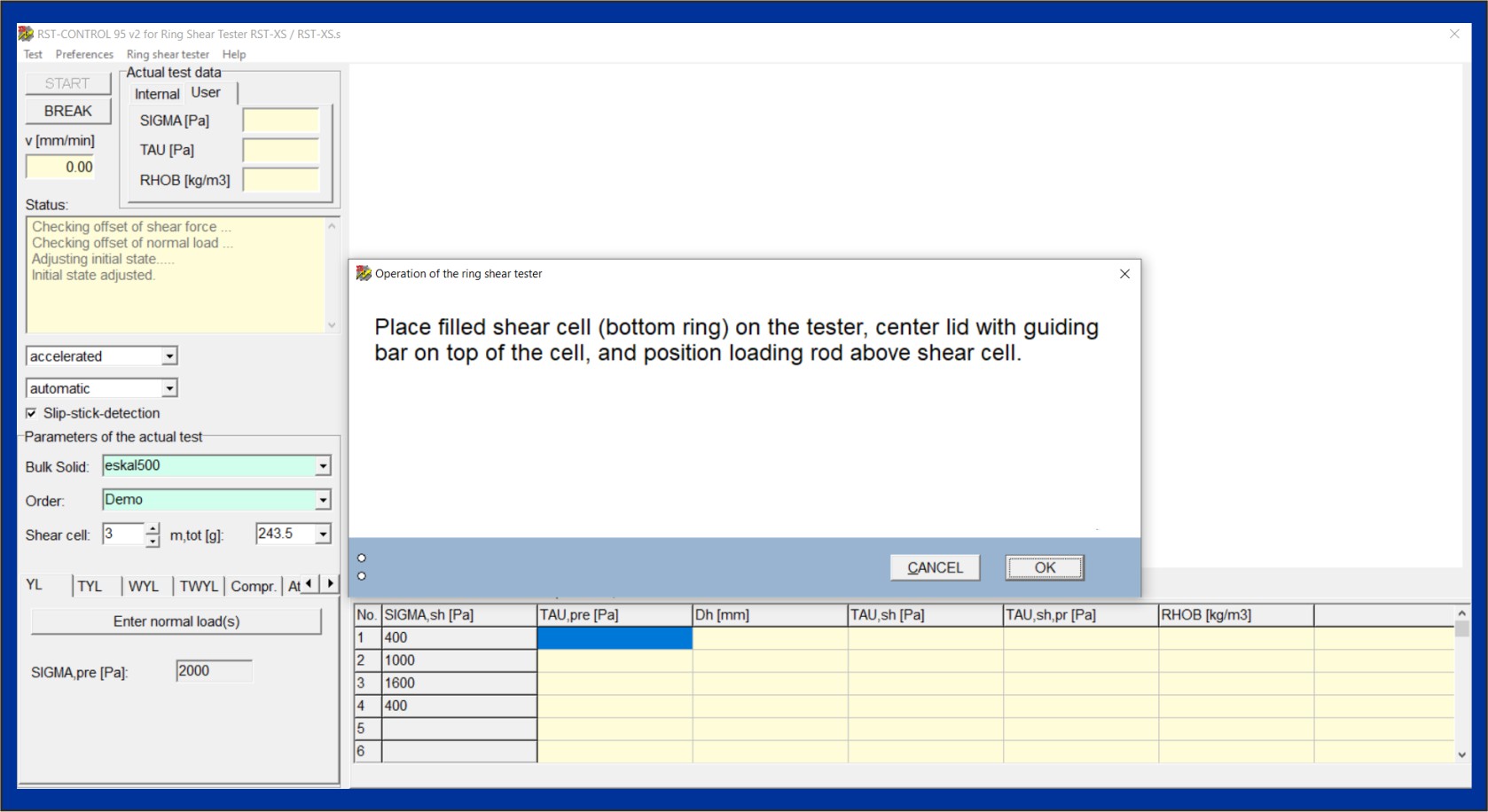

After the normal stresses, the name of the sample and the mass of

the filled shear cell have been entered, the test procedure is

started. As shown in the picture below, RST-CONTROL 95 guides you

through the procedure: Place the shear cell on the tester, etc.

This can also be done by voice output if the ring shear tester is

a little distant from the PC.

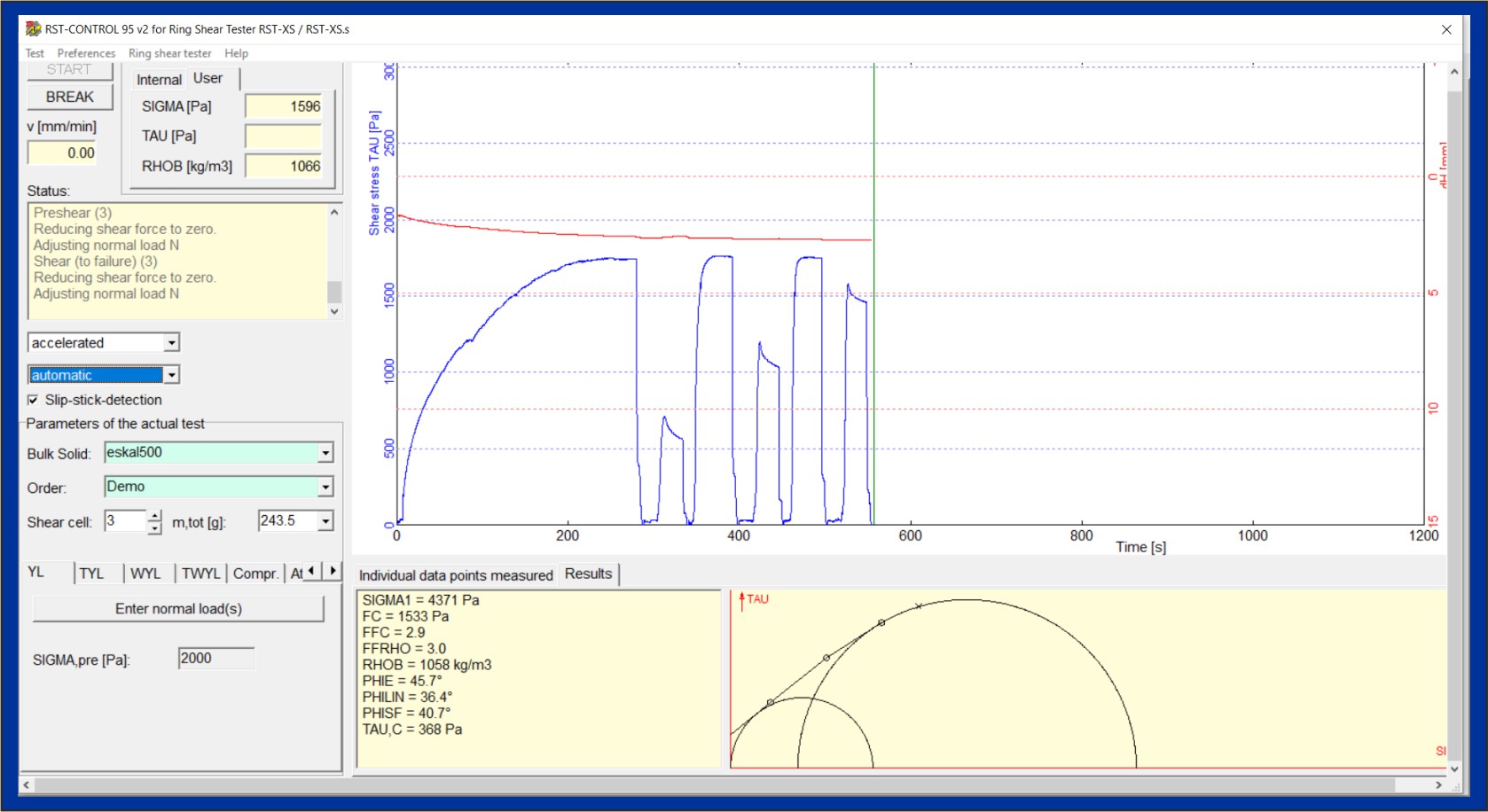

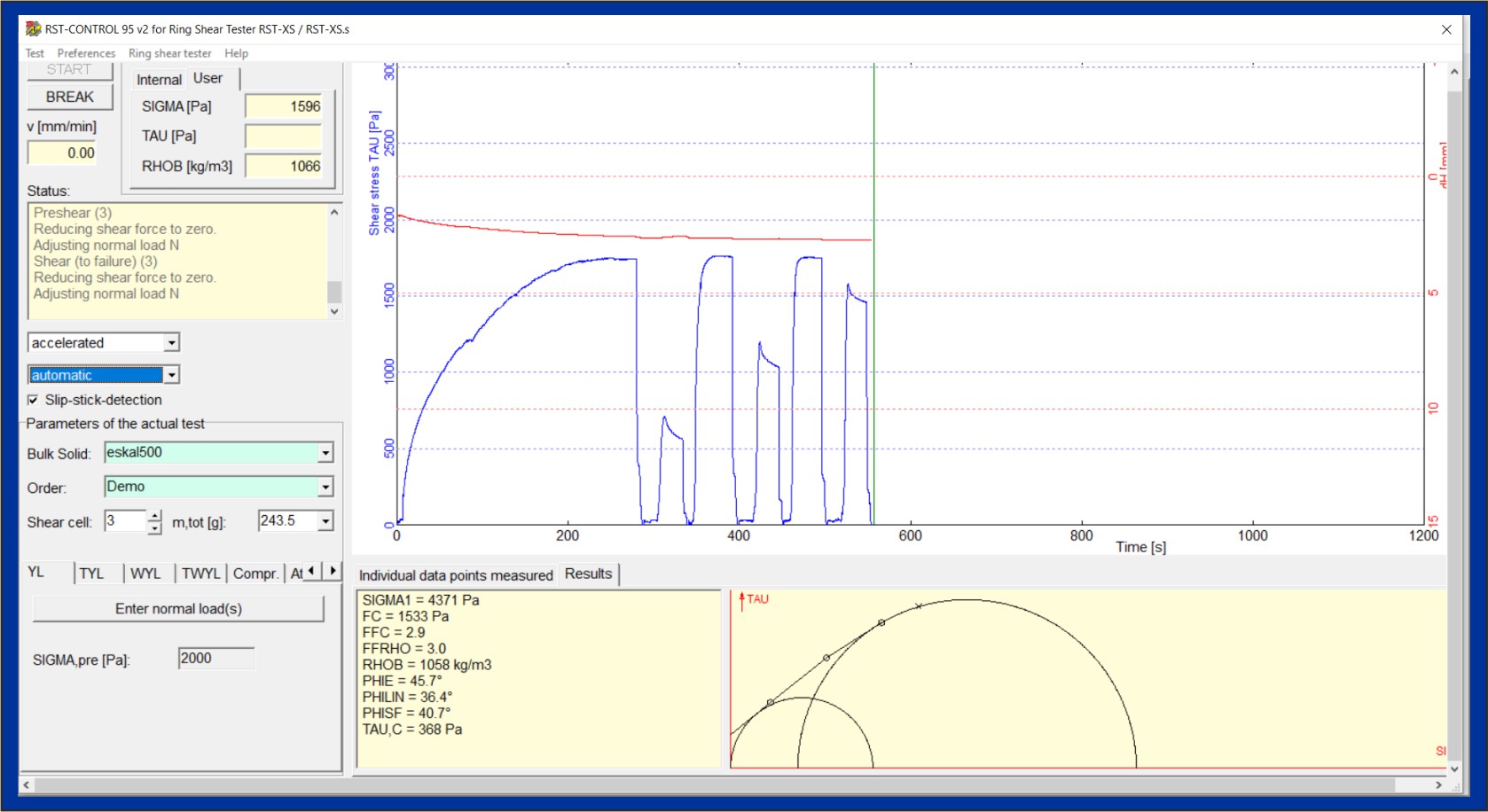

After the shear is placed on and connected to the tester, the

automatic test procedure begins. On the image below, the specimen

has already been presheared and sheared to failure three times for

the measurement of a yield locus. The blue curve shows the shear

stress over time. Due to the increase of bulk density, caused by

the consolidation process, the shear cell lid has moved downward

somewhat as shown by the descending course of the red curve "lid

displacement". In the lower part of the image, the preliminary

evaluation has been activated, where the yield locus constructed

from the points already measured is displayed with the associated

flow properties to the left (e.g., FC = unconfined yield strength,

RHOB = bulk density).

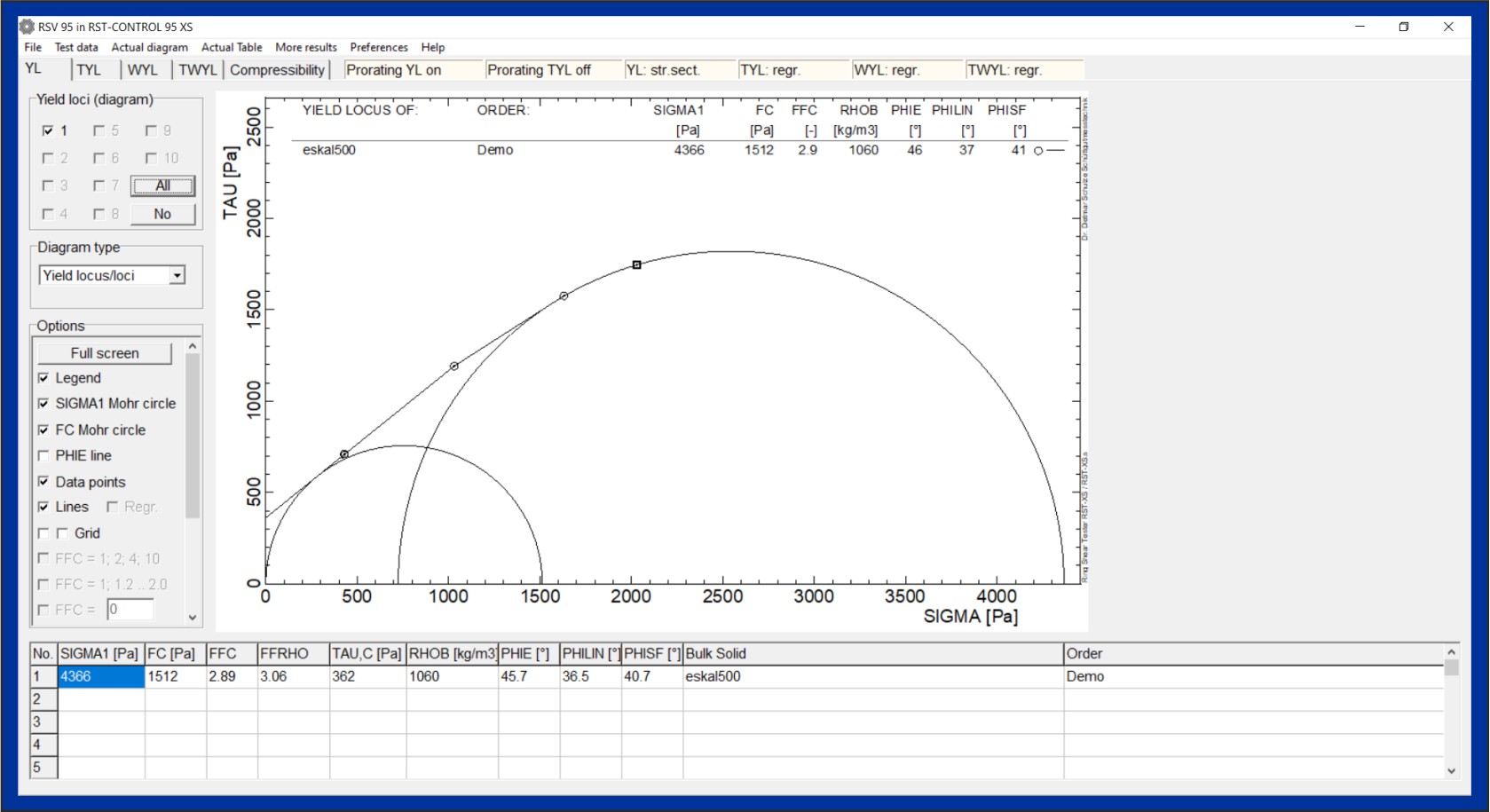

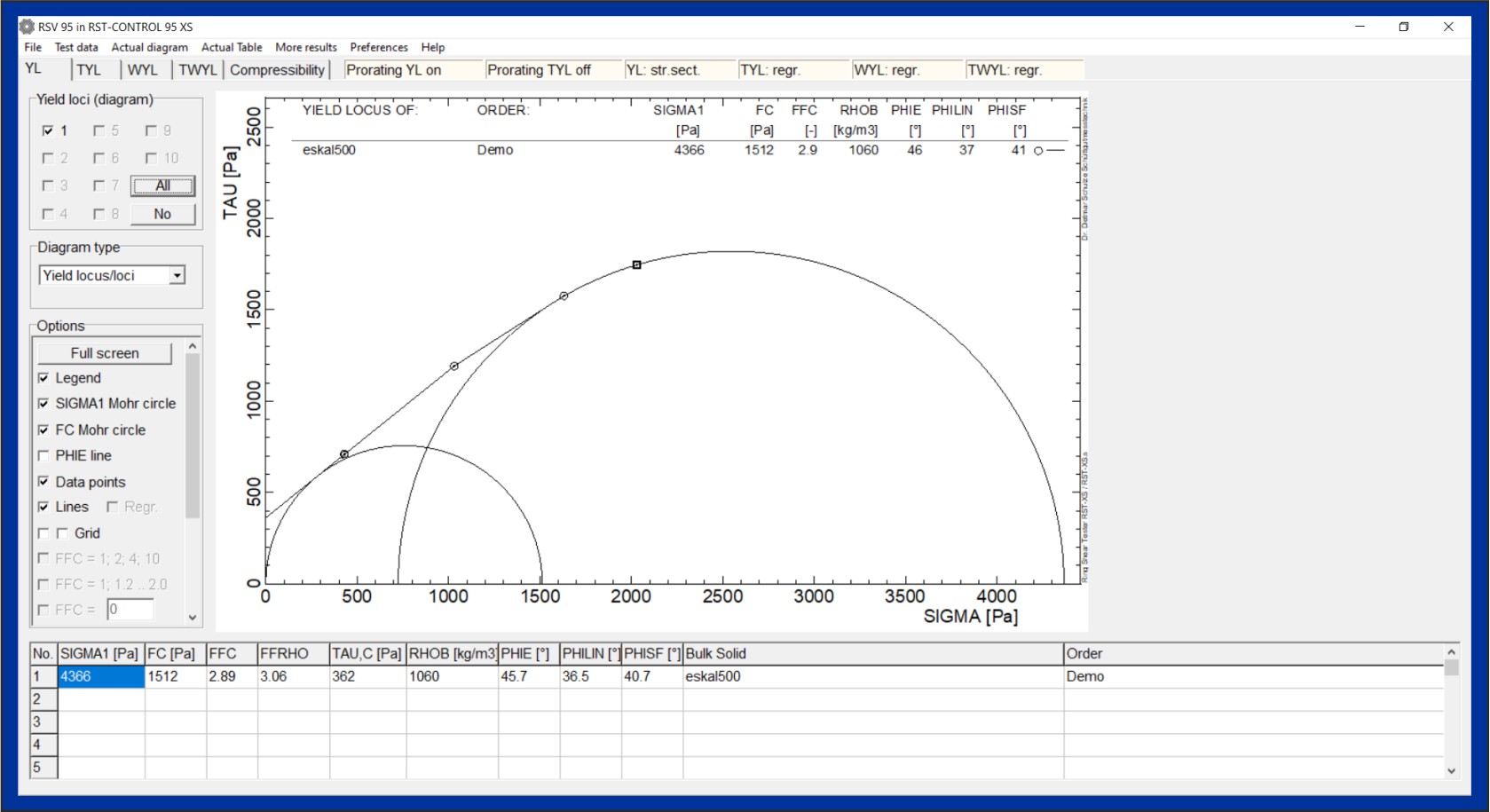

After completion of the test, the measurement data are saved. On

the evaluation window (picture below, shown is the previously

measured yield locus with the flow properties) the test results

can then be viewed in detail or evaluated differently, and printed

or exported as a graphic or table. Furthermore, other measurements

can be added to compare the test results (e.g. the flow behavior

of different samples or mixtures). Furthermore, the output files

generated by RST-CONTROL 95 can be imported by the program CAHD -

computer-aided hopper design.

System requirements

PC running Microsoft Windows® 7/8/10/11*, screen

resolution min. 1024x768, one free serial communication port or

USB port. For the acoustic user guide (optional) sound card and

speakers are required.

* Microsoft Windows® 7, Windows®

8, Windows® 10, and Windows® 11 are registered

trademarks of Microsoft Corp., U.S.A.

Technical modifications and errors excepted.