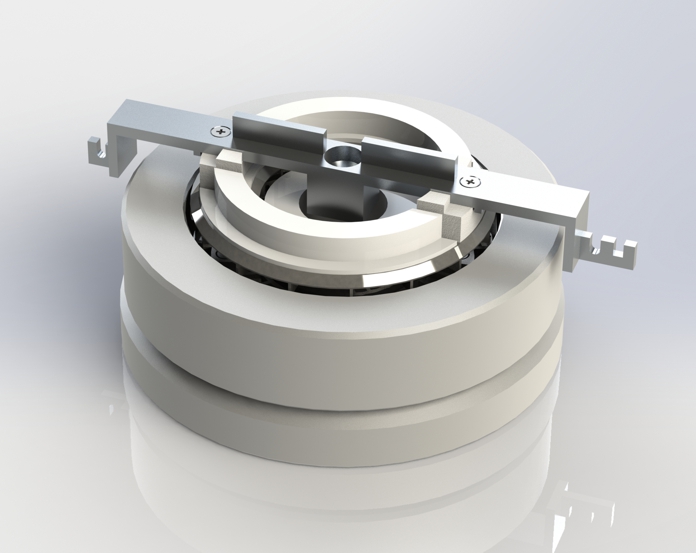

Shear cells

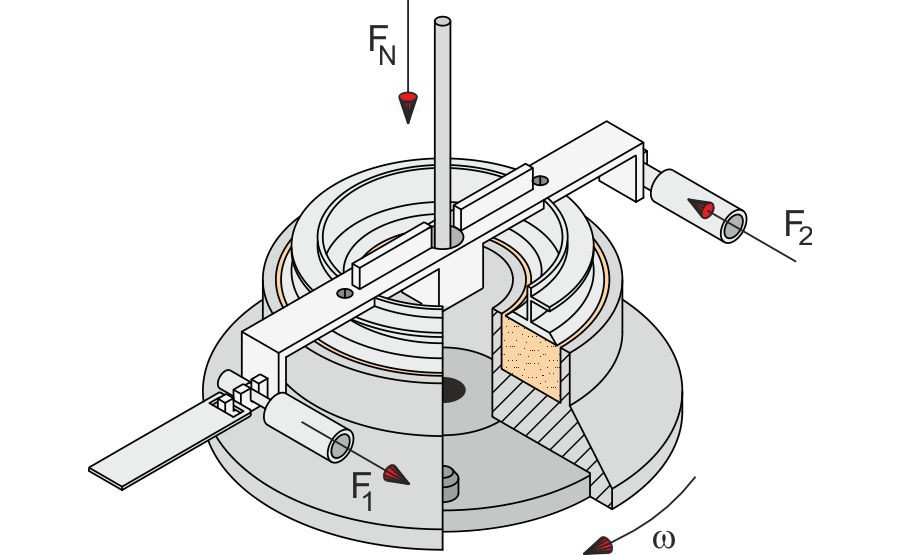

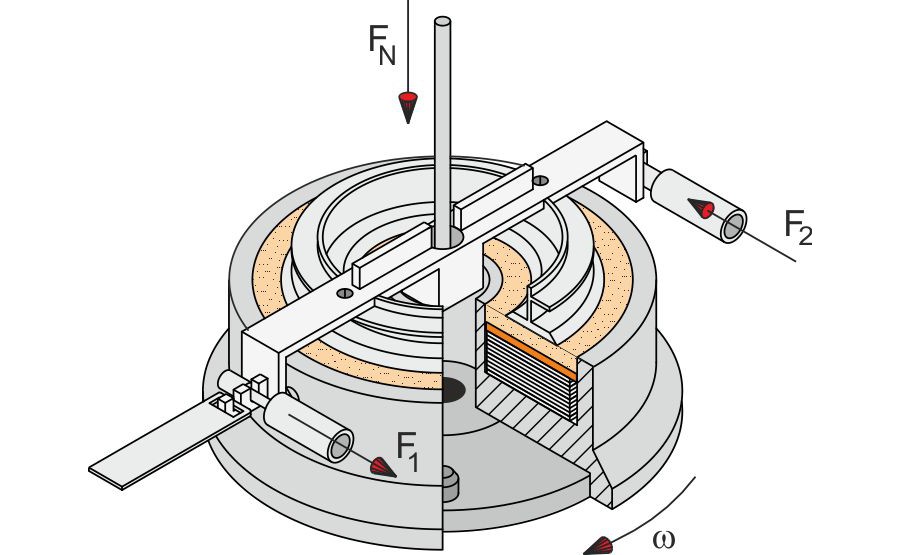

Ring

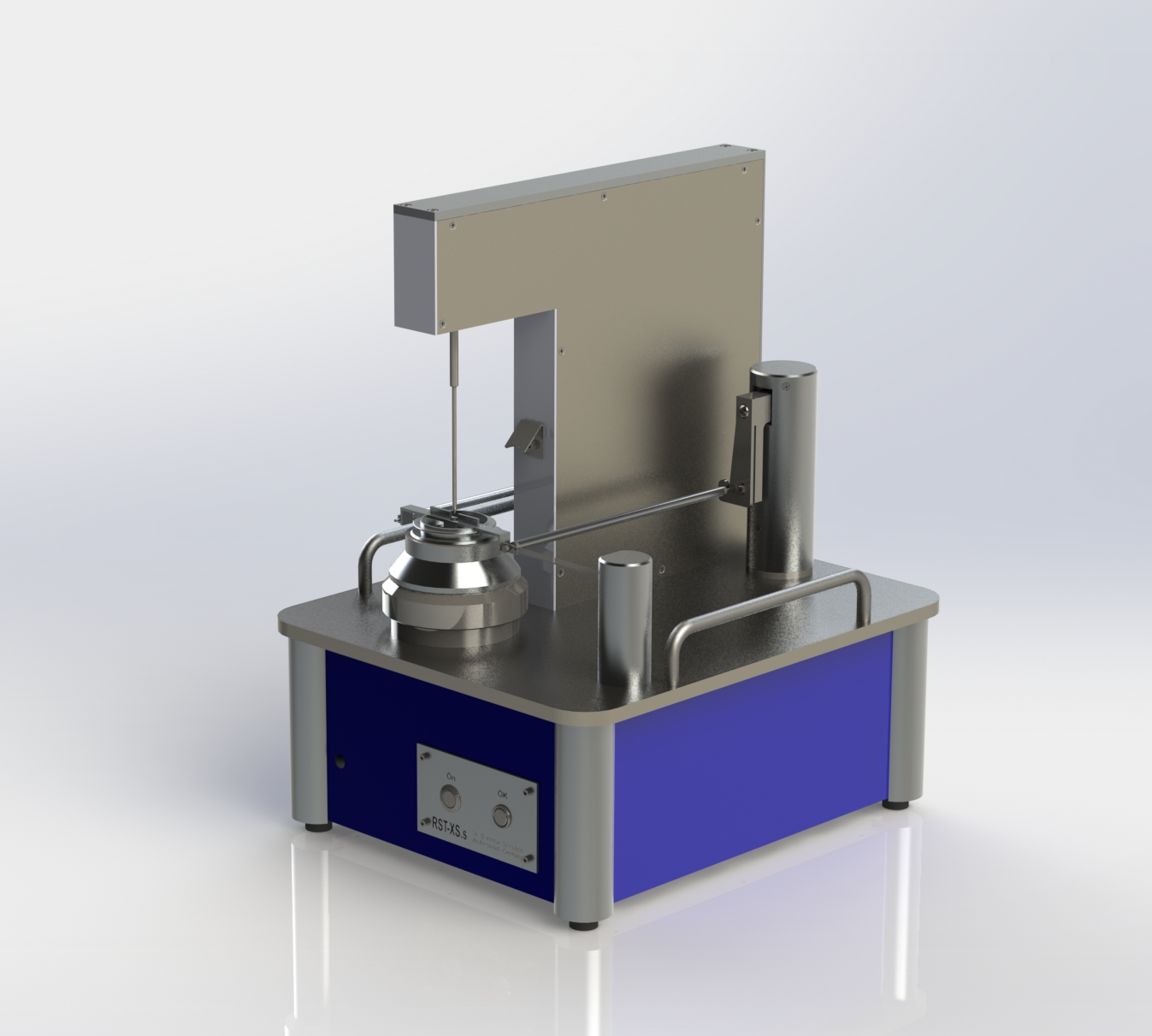

Shear Testers RST-XS.s are generally delivered with one

shear cell type XS-Mr which is called the "standard shear

cell". For coarser powders a larger shear cell, type XS-Lr,

is available (data see below).

Ring

Shear Testers RST-XS.s are generally delivered with one

shear cell type XS-Mr which is called the "standard shear

cell". For coarser powders a larger shear cell, type XS-Lr,

is available (data see below).

If

only very limited amounts of powder are available for

testing, shear cell types XS-MV4, XS-Sr or XS-SV3 with

specimen volumes of 3.5 to 10 ml can be used. The table

below gives an overview.

If

only very limited amounts of powder are available for

testing, shear cell types XS-MV4, XS-Sr or XS-SV3 with

specimen volumes of 3.5 to 10 ml can be used. The table

below gives an overview.

| Name |

Description |

| XS-Mr |

"Standard shear cell" with about 30 ml specimen

volume, cross-section about 24 cm²

Maximum particle size depends on the type of powder

and is about 1 mm for broad particle size

distributions and 0.5 mm for narrow particle size

distributions. |

| XS-Lr |

"Large volume": About 70 ml specimen volume,

cross-section about 46 cm²

Applicable for coarser materials than XS-Mr.

Lid provided with vanes similar to XS-Mr.

Maximum particle size depends on the type of powder

and is about 1.5 mm for broad particle size

distributions and 0.75 mm for narrow particle size

distributions. |

| XS-Sr |

"Small volume": About 10 ml specimen

volume, cross-section about 13.5 cm²

Lid provided with vanes similar to XS-Mr.

Maximum particle size depends on the type of powder

and is about 0.5 mm for broad particle size

distributions and 0.25 mm for narrow particle size

distributions. |

| XS‑MV4 |

"Small volume": About 9.5 ml specimen

volume, cross-section about 24 cm²

Lid and bottom rough, no vanes.

Maximum particle size depends on the type of powder

and is about 0.5 mm for broad particle size

distributions and 0.25 mm for narrow particle size

distributions. |

| XS-SV3 |

"Very small volume": About 3.5 ml specimen

volume, cross-section about 13.5 cm²

Lid and bottom rough, no vanes.

Maximum particle size depends on the type of powder

and is about 0.3 mm for broad particle size

distributions and 0.2 mm for narrow particle size

distributions. |

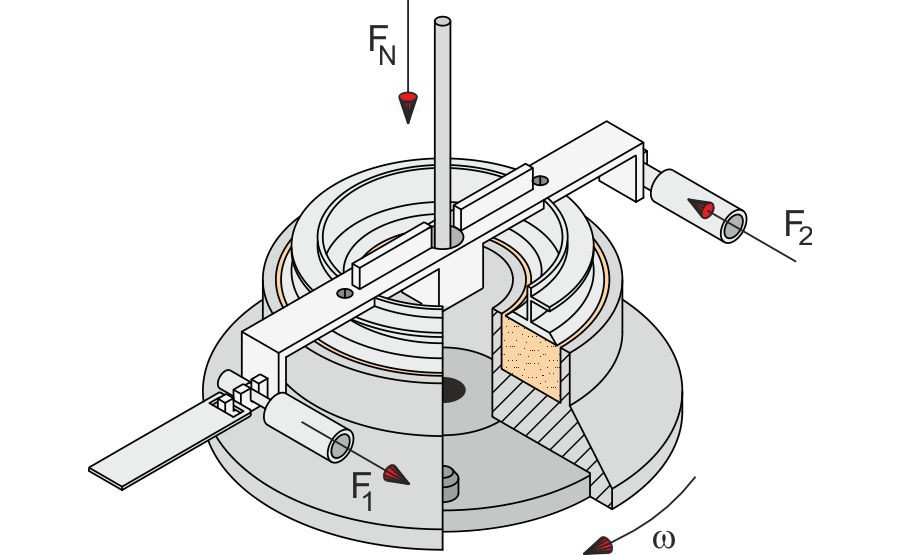

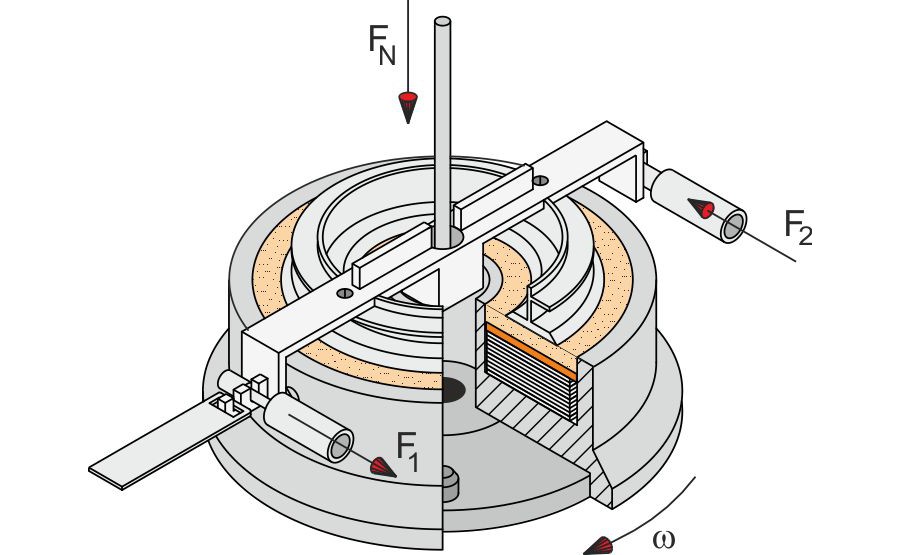

Wall friction cells

Wall

friction cells are required for the measurement of the wall

friction angle or coefficient of wall friction (friction

between a bulk solid and a wall material). For the test, an

annular wall material specimen ("coupon") is placed in the

shear cell with the bulk solid specimen on top, i.e., the

bulk solid is located above the wall material like on a

hopper wall or a chute, which is absolutely necessary in

order to avoid underestimating the wall friction angle in

the case of segregating bulk solids.

Wall

friction cells are required for the measurement of the wall

friction angle or coefficient of wall friction (friction

between a bulk solid and a wall material). For the test, an

annular wall material specimen ("coupon") is placed in the

shear cell with the bulk solid specimen on top, i.e., the

bulk solid is located above the wall material like on a

hopper wall or a chute, which is absolutely necessary in

order to avoid underestimating the wall friction angle in

the case of segregating bulk solids.

Wall

material coupons can be made by the customer according to

dimensions given in the tester's manual.

Wall

material coupons can be made by the customer according to

dimensions given in the tester's manual.

| Name |

Description |

| XS-WM |

"Standard" wall friction cell, specimen volume

about 20 ml, outer diameter of the wall material

coupon about 75 mm. |

| XS‑WL0 |

Wall friction cell (low stresses) with specimen

volume of about 30 ml, outer diameter of the

wall material coupon about 88 mm |

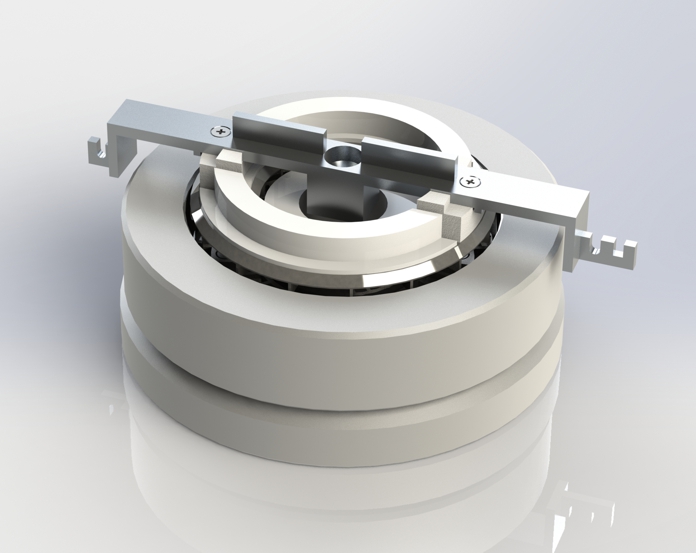

Low stress shear cells

For the Ring

Shear Tester RST-XS.s we offer a shear cell and a wall

friction cell to achieve even lower stresses. Here the shear

lid is attached to the loading rod ("hanging lid"). Fine

resolution of measured stresses is achieved due to the large

cross-sectional area.

For the Ring

Shear Tester RST-XS.s we offer a shear cell and a wall

friction cell to achieve even lower stresses. Here the shear

lid is attached to the loading rod ("hanging lid"). Fine

resolution of measured stresses is achieved due to the large

cross-sectional area.

| Name |

Description |

| XS‑Lr0 |

Dimensions similar to XS-Lr (volume about 70 ml,

cross-section about 46 cm², lid provided with vanes)

|

| XS‑WL0 |

Wall friction cell with specimen volume of about

30 ml, outer diameter of the wall material

coupon about ca. 88 mm |

Compressibility cells

A

compressibility cell serves to determine the function of

bulk density in terms of stress as accurately as possible.

Due to the flat cylindrical sample space, the influence of

wall friction is minimized.

A

compressibility cell serves to determine the function of

bulk density in terms of stress as accurately as possible.

Due to the flat cylindrical sample space, the influence of

wall friction is minimized.

| Name |

Description |

| XS‑VM |

Compressibility cell (approx. 48 ml specimen

volume, 64 mm specimen diameter). |

| XS‑VS |

Compressibility cell (approx. 20 ml specimen

volume, 48 mm specimen diameter). |

Time consolidation benches

A time consolidation test examines how a bulk solid

consolidates when it is stored at rest (e.g. in a silo or

IBC). To measure this, the bulk solid specimen is first

consolidated with the ring shear tester, then stored under

constant load, and finally sheared to failure. All of this

can be done automatically with the ring shear tester,

without having to remove the shear cell with the bulk solid

specimen from the tester. The disadvantage, however, is that

the tester is blocked by this specimen. Therefore, the use

of a time-consolidation bench for external storage is

recommended.

When using a time consolidation bench, the specimen is

consolidated with the ring shear tester, then removed from

the tester and placed on a time consolidation bench. The

consolidation stress is exerted on the specimen through

weights. After the consolidation period is over (e.g., after

some hours, a day or a week), the specimen is returned to

the ring shear tester and sheared again to measure the

strength of the consolidated powder. Thus, one obtains a

quantitative result on the increase of strength during the

consolidation time, which is known as "caking".

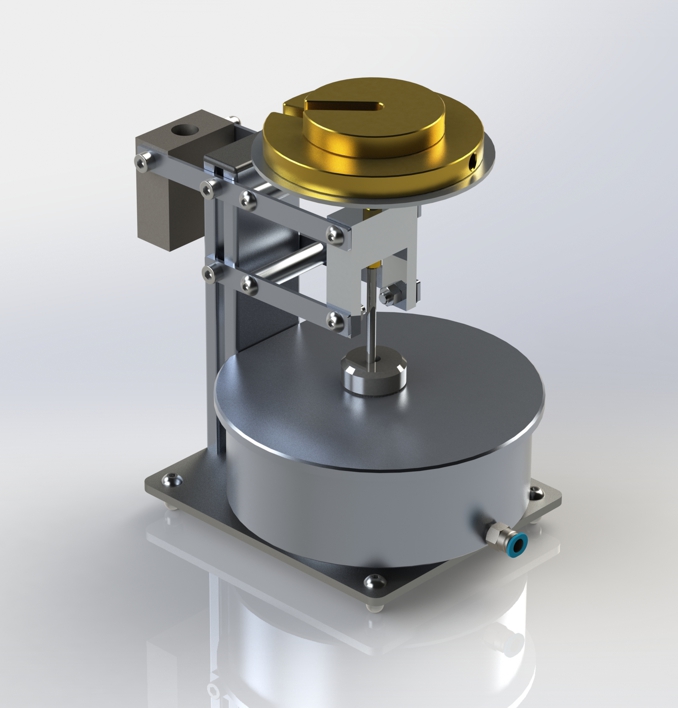

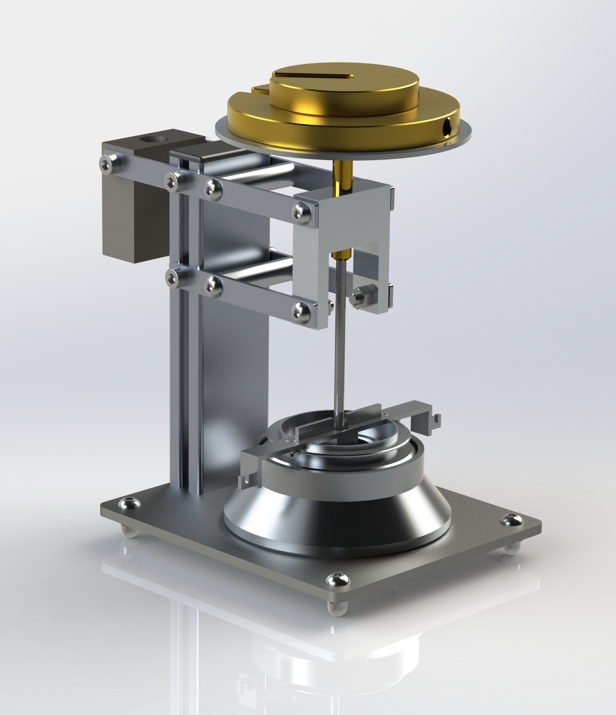

The

open time consolidation stand (type XS-1O) is used to store

a powder specimen under load. The consolidation stress is

generated by weights and applied to the shear cell via a

vertical rod. The loading mechanism is equipped with a

counterweight, which compensates for the dead weight of the

device.

The

open time consolidation stand (type XS-1O) is used to store

a powder specimen under load. The consolidation stress is

generated by weights and applied to the shear cell via a

vertical rod. The loading mechanism is equipped with a

counterweight, which compensates for the dead weight of the

device.

The design without cover allows contact between the powder

specimen and the ambient atmosphere. This is preferable if

the behavior of the powder in dependence on the ambient

conditions has to be studied, e.g. by storing the time

consolidation bench with the shear cell and the powder

specimen in a climate cabinet.

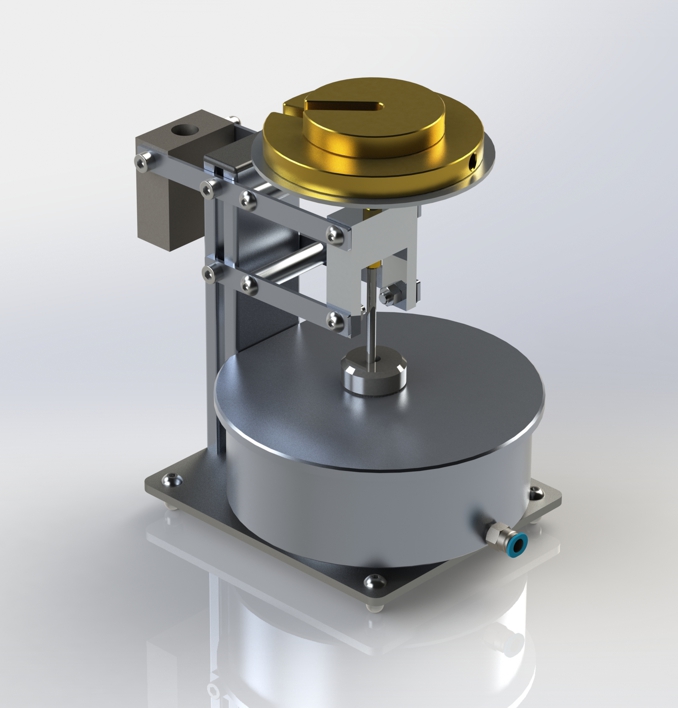

The

picture on the right shows the closed version of the time

consolidation stand (type XS-1C). The shear cell, which is

not visible on the image, is located in the cylindrical

protective container, which serves to shield the shear cell

from the ambient atmosphere. Conditioned air or gas can be

blown into the interior of the protective container via a

hose connection.

The

picture on the right shows the closed version of the time

consolidation stand (type XS-1C). The shear cell, which is

not visible on the image, is located in the cylindrical

protective container, which serves to shield the shear cell

from the ambient atmosphere. Conditioned air or gas can be

blown into the interior of the protective container via a

hose connection.

The XS-1C time consolidation stand is based on the XS-1O

open time consolidation stand, which is fitted with a

protective cover. Existing time consolidation stands of type

XS-1O can be converted to type XS-1C by adding the

protective cover.

Shear cell and driving axle for increased temperature

consistency of preheated specimens

Shear

cell XS-MTL was developed for the examination of samples at

temperatures below or above room temperature. It is

characterized by increased heat capacity (greater intrinsic

mass) and reduced heat transfer to both the tester and the

environment. This means that a powder sample previously

tempered with the shear cell can be examined with the

RST-XS.s (or RST-XS) ring shear tester. The temperature

change is significantly reduced compared to normal shear

cells.

Shear

cell XS-MTL was developed for the examination of samples at

temperatures below or above room temperature. It is

characterized by increased heat capacity (greater intrinsic

mass) and reduced heat transfer to both the tester and the

environment. This means that a powder sample previously

tempered with the shear cell can be examined with the

RST-XS.s (or RST-XS) ring shear tester. The temperature

change is significantly reduced compared to normal shear

cells.

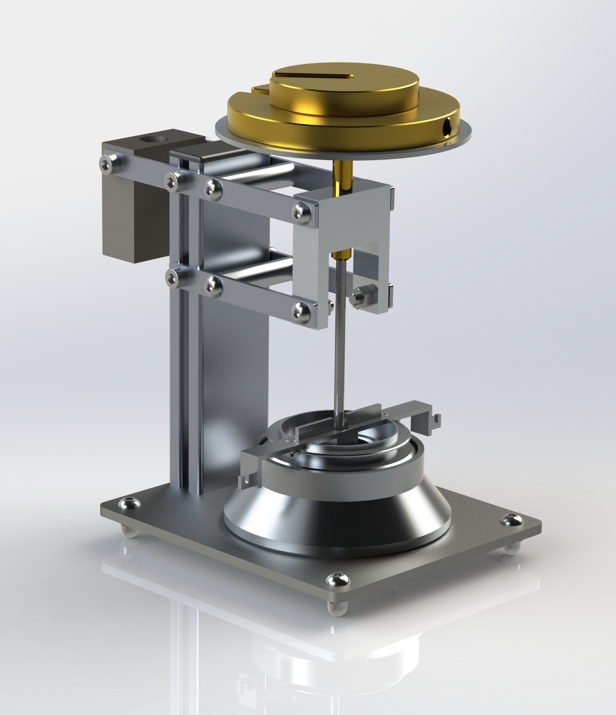

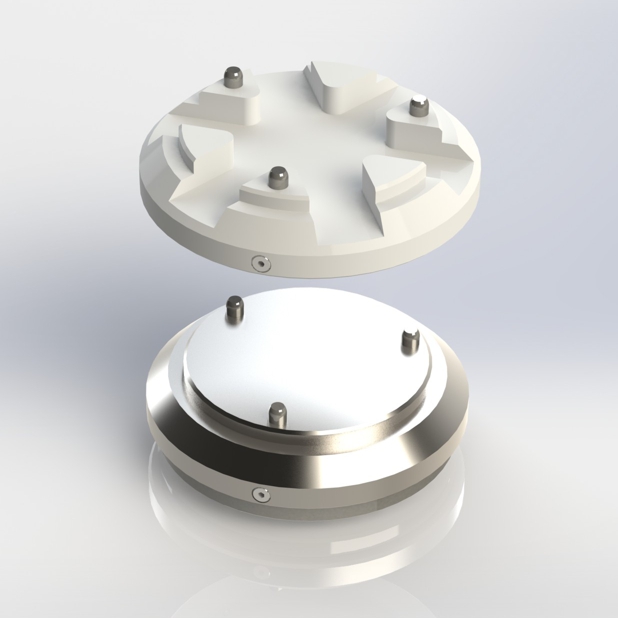

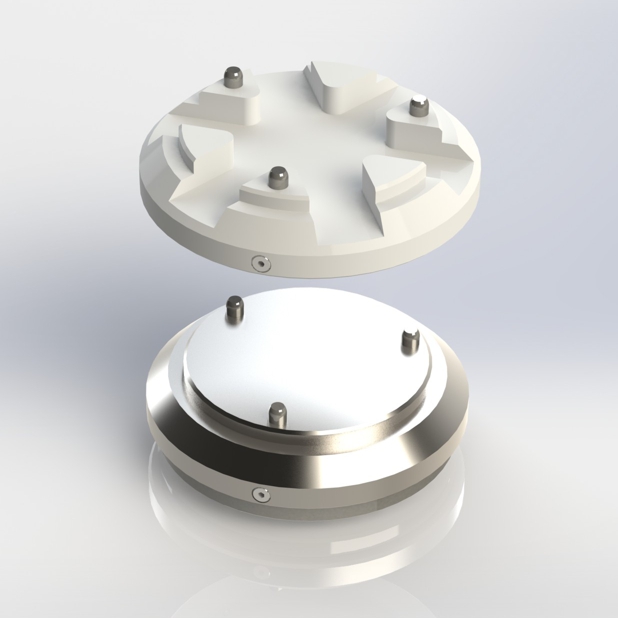

The

heat

transfer from the shear cell (type XS-MTL or another type)

to the tester can be further reduced if a (retrofittable)

driving axle with exchangeable top part made of PTFE is

used. The small picture (left) shows this driving axle

with top part made of stainless steel and above it the

alternative PTFE top part.

The

heat

transfer from the shear cell (type XS-MTL or another type)

to the tester can be further reduced if a (retrofittable)

driving axle with exchangeable top part made of PTFE is

used. The small picture (left) shows this driving axle

with top part made of stainless steel and above it the

alternative PTFE top part.

In addition, tempered gas can be supplied with a

protective cover (see below), in order to further improve

the temperature constancy of the powder sample.

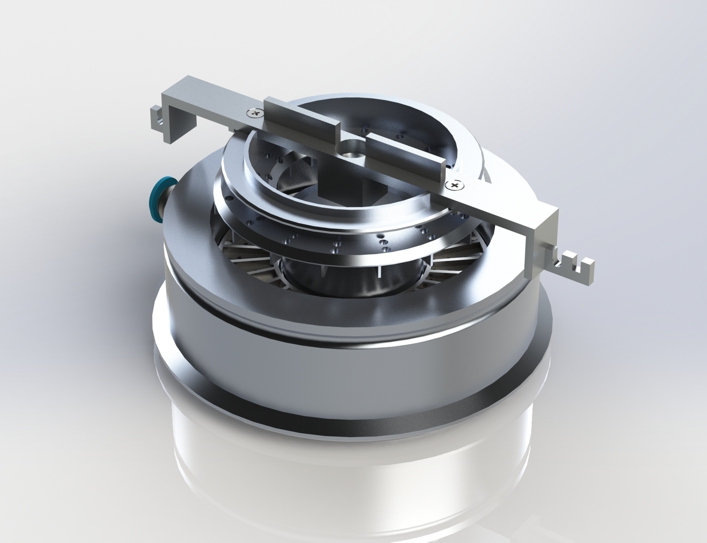

Gas flow shear cell

With the XS-MA gas flow shear cell, gas can flow

through a specimen during measurement, e.g., to achieve a

defined moisture or gas composition within the powder

specimen. A hose connection is used to supply gas from

below, and the gas can exit through a perforated cover and

the gap between the annular lid and bottom ring.

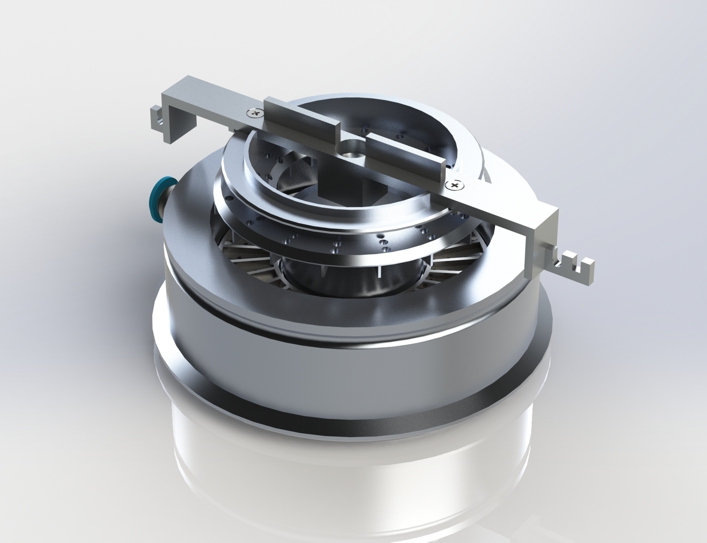

Protective cover for gas supply

If

powders have to be tested at a specific atmosphere, e.g., to

prevent change of moisture, or to reduce the risk of

spontaneous combustion, the RST-XS.s can be provided with a

cover around the shear cell (see image). The protective

cover can be supplied with (inert) gas through a hose

fitting for gas supply.

If

powders have to be tested at a specific atmosphere, e.g., to

prevent change of moisture, or to reduce the risk of

spontaneous combustion, the RST-XS.s can be provided with a

cover around the shear cell (see image). The protective

cover can be supplied with (inert) gas through a hose

fitting for gas supply.

The protective cover is provided with openings for tie rod

and push rod for shear force measurement, for the bar of the

horizontal guiding system, and the loading rod of the normal

load system. Since the openings must remain open during

testing, it is necessary to supply gas permanently.

The protective cover can also be used to suck off gas from

the space around the shear cell.

Weights

For time consolidation tests in combination with the time

consolidation bench (see above) weights are required for the

adjustment of the consolidation load.

Available sizes:

2 kg, 1 kg, 0.5 kg, 0.2 kg, 0.1 kg.

Accuracy: min. +/- 1%

Dimensions: thickness 10 mm to 14 mm, other dimensions

depend on weight.

Weights are available as set or separately.