Application and overview

Ring Shear Testers serve for the determination of flow properties

of powders and bulk solids like pharmaceutical powders, flour,

cement, soap powder, titanium dioxide, clay, sewage sludge, and

others. Thus, a Ring Shear Tester may be called a powder tester,

powder flow analyzer, bulk solid flow tester, or flow property

tester, and sometimes it's called a shear cell tester or just ring

shear cell. However, being a real shear tester, the Ring Shear

Tester is a very accurate powder tester providing physical

quantities to characterize powder flow. Results can be applied on

product optimization, quality control, or characterization of

powder flow, but also on quantitative design procedure like hopper

design for flow. Thus, our Ring shear testers are applied in

a wide range of industry (e.g. Chemical Industry, Pharmaceutical

Industry, Food Industry), and in universities and research

institutions as well.

The most important flow properties of powders and bulk solids are:

Flowability, compressive strength, internal friction, time

consolidation, wall friction, and bulk density. These are

important (and physically-defined) quantities for the

characterization of powders More about these terms you will find

in an essay on this website (click

here) and - somewhat shorter - on an information sheet which

can be downloaded here as pdf file.

Typical applications for the ring shear testers are product

characterization, quality control, comparative tests, and silo

design.

An impression of the operation...

... of a Ring Shear Tester is given by the following example:

Small and large Ring Shear Tester

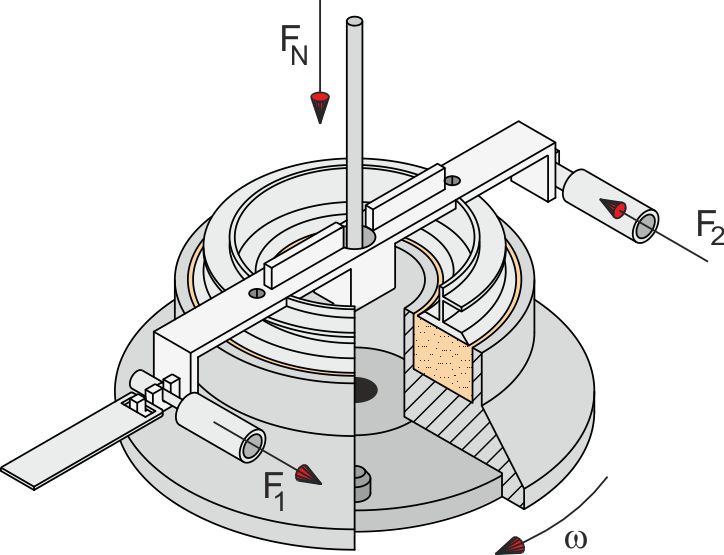

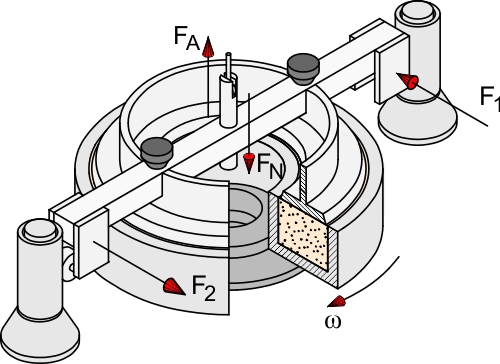

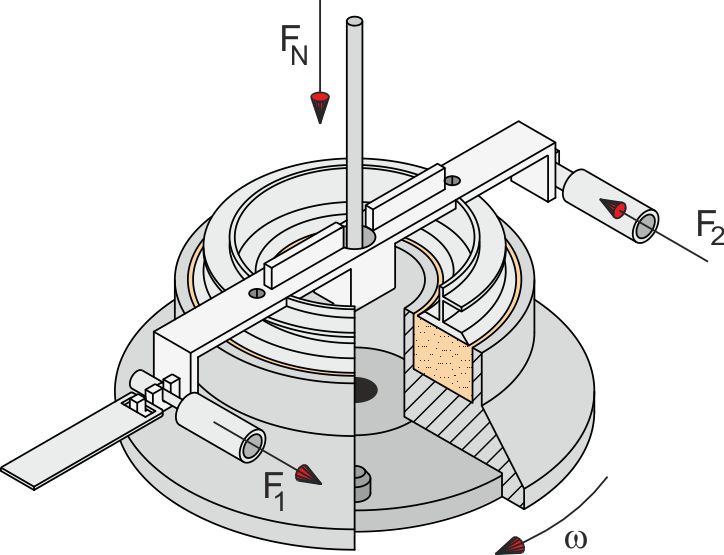

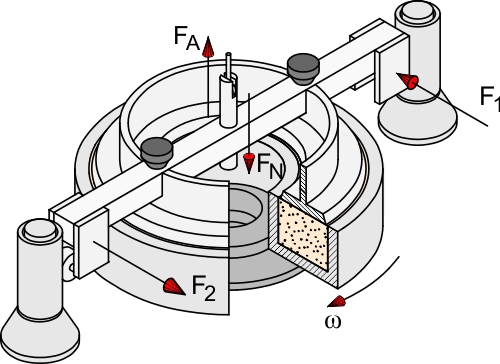

The principle of both Ring Shear Testers is the same: A

powder or bulk solid specimen is contained in a ring-shaped

(annular) trough, called the bottom ring, covered by an

annular lid and subjected to a vertical load through the

lid. The specimen is then subjected to a shear deformation

by rotating the bottom ring relative to the lid. From the

normal stress and the shear stress measured following

different procedures a couple of quantities is determined,

e.g., the unconfined yield strength (compressive strength),

the flowability, the internal friction, the bulk density.

The major difference between the testers is the size of the

shear cells. which determines the maximum particle size that

can be tested. This limitation results from the conditions

that a sufficient number of particles must be contained in

the shear cell to obtain a continuum, i.e., a "powder"

or "bulk solid" instead of "some particles".

If the materials to be tested do not contain particles

greater than about 1 mm, the small tester is sufficient. If

larger particles have to be tested, the large tester is

preferable. Since the maximum particle size is the critical

point, it is no problem to test very fine particles in the

range of micrometers or even nanometers in a large

tester.

The selection guide shows further criteria to identify the best

tester for your application:

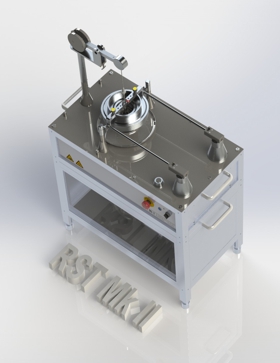

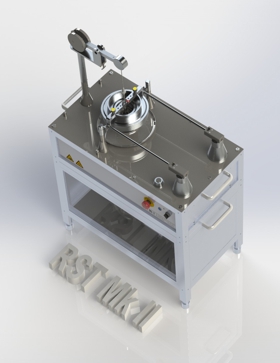

Ring shear tester RST Mk II

The Ring Shear

Tester Mk II, successor type RST-01.pc, is suited for all

powders and bulk solids up to a particle size of 5 .. 10 mm

(depends on particle size distribution). It performs the tests

automatically, i.e. controlled by a Personal Computer and

control software RST-CONTROL.

The Ring Shear

Tester Mk II, successor type RST-01.pc, is suited for all

powders and bulk solids up to a particle size of 5 .. 10 mm

(depends on particle size distribution). It performs the tests

automatically, i.e. controlled by a Personal Computer and

control software RST-CONTROL.

The RST Mk II is our most versatile tester due to the

possibility of measuring powders and bulk solids with particle

sizes from "0" to several millimeters. Thus, it is

advantageous in areas where not only fine powders are to be

tested, e.g., in silo construction and in the areas of food,

feed, chemicals and raw materials.

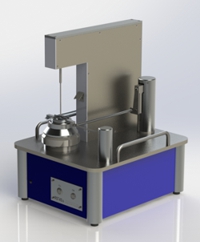

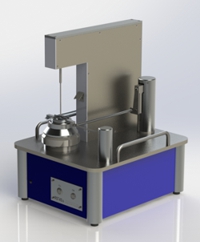

Ring shear tester RST-XS.s

The "small" Ring

Shear Tester RST-XS.s is first of all an automatic flowability

and caking tester for fine-grained powders. If is a bench-top

device, much smaller than the RST Mk II, and serves as

flowability and caking tester at many places, but is also used

for the design of hoppers and silos.

The "small" Ring

Shear Tester RST-XS.s is first of all an automatic flowability

and caking tester for fine-grained powders. If is a bench-top

device, much smaller than the RST Mk II, and serves as

flowability and caking tester at many places, but is also used

for the design of hoppers and silos.

The RST-XS.s is usually placed on a laboratory bench and is easy

to operate. Because of the small required powder specimen (only

about 30 ml for the standard shear cell, about 3.5 ml for the

smallest shear cell) this tester can be applied also in

industries where only small amounts of powder are available for

testing, e.g. in Pharmaceutical Industry.

Why don't we call the Ring Shear Tester "powder

rheometer"?

We deliberately do not use the designation "rheometer". A ring

shear tester, or ring shear cell, is a shear tester. Shear

testers for measuring the properties of powders and bulk solids

originate from the scientific work of A.W. Jenike, the founder

of modern bulk solids technology.

A good shear tester is optimized to have accurate control over

stresses (e.g., applying a constant normal stress), and then to

measure friction (or strength) as accurately as possible. In

strength measurement, a powder or bulk solid is first

consolidated with the shear tester, then set to flow while the

shear stress required to initiate flow is measured. This gives

us information not only on flowability but also to the physical

quantities required for quantitative hopper design (mass flow,

no arching, no rathole formation), and also for structural silo

design.

In contrast to the typical rheometer, which is historically used

to measure properties of fluids, e.g., viscosity, the shear rate

plays a minor role in the shear tester.