Time consolidation benches

A time consolidation test examines how a bulk solid

consolidates when it is stored at rest (e.g. in a silo or

IBC). To measure this, the bulk solid specimen is first

consolidated with the ring shear tester, then stored under

constant load, and finally sheared to failure. All of this

can be done automatically with the ring shear tester,

without having to remove the shear cell with the bulk solid

specimen from the tester. The disadvantage, however, is that

the tester is blocked by this specimen. Therefore, the use

of a time-consolidation bench for external storage is

recommended.

When using a time consolidation bench, the specimen is

consolidated with the ring shear tester, then removed from

the tester and placed on a time consolidation bench. The

consolidation stress is exerted on the specimen through

weights. After the consolidation period is over (e.g., after

some hours, a day or a week), the specimen is returned to

the ring shear tester and sheared again to measure the

strength of the consolidated powder. Thus, one obtains a

quantitative result on the increase of strength during the

consolidation time, which is known as "caking".

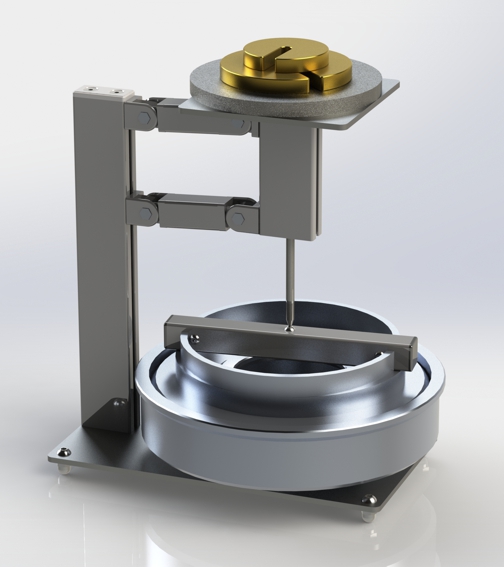

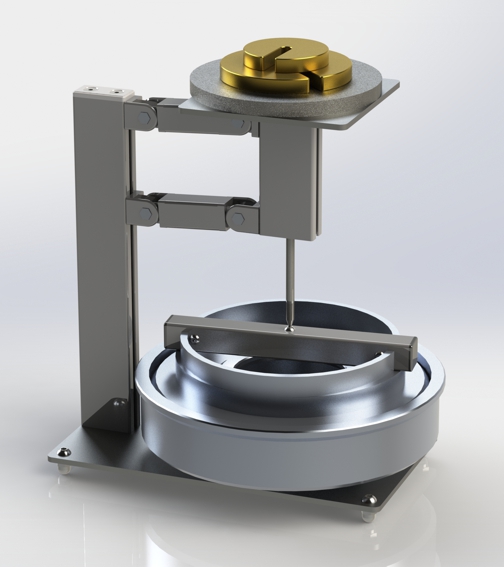

The

time consolidation bench without cover (type 1SM-O) serves

for the storage of one shear cell (type M, S or XS, maximum

load 15 kg). The consolidation load is transferred to the

powder specimen through a vertical loading system provided

with a plate on top on which an appropriate amount of

weights is placed.

The

time consolidation bench without cover (type 1SM-O) serves

for the storage of one shear cell (type M, S or XS, maximum

load 15 kg). The consolidation load is transferred to the

powder specimen through a vertical loading system provided

with a plate on top on which an appropriate amount of

weights is placed.

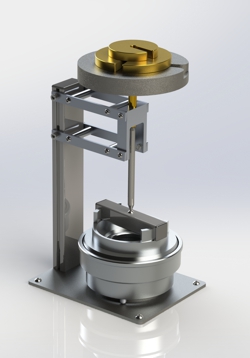

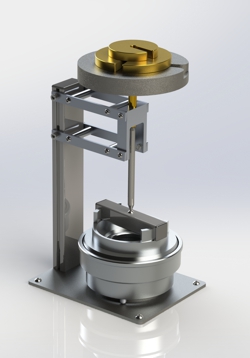

The

time consolidation bench type 1S-O serves for the storage of

one shear cell type S ore XS (volume ca. 200 ml, maximum

load 15 kg). The consolidation load is transferred to the

powder specimen through a vertical loading system provided

with a plate on top on which an appropriate amount of

weights is placed. The design without cover allows a more

intensive contact between the powder specimen and the

ambient atmosphere. This is preferable if the behavior of

the powder in dependence on the ambient conditions has to be

studied, e.g. by storing the time consolidation bench with

shear cell and powder specimen in a climate cabinet or an

oven.

The

time consolidation bench type 1S-O serves for the storage of

one shear cell type S ore XS (volume ca. 200 ml, maximum

load 15 kg). The consolidation load is transferred to the

powder specimen through a vertical loading system provided

with a plate on top on which an appropriate amount of

weights is placed. The design without cover allows a more

intensive contact between the powder specimen and the

ambient atmosphere. This is preferable if the behavior of

the powder in dependence on the ambient conditions has to be

studied, e.g. by storing the time consolidation bench with

shear cell and powder specimen in a climate cabinet or an

oven.

The

picture on the right shows the closed time consolidation

stand 1S-C. The shear cell, which is not visible on the

image, is located in the cylindrical protective container,

which serves to shield the shear cell from the ambient

atmosphere. Conditioned air or gas can be blown into the

interior of the protective container via a hose connection.

The

picture on the right shows the closed time consolidation

stand 1S-C. The shear cell, which is not visible on the

image, is located in the cylindrical protective container,

which serves to shield the shear cell from the ambient

atmosphere. Conditioned air or gas can be blown into the

interior of the protective container via a hose connection.

The 1S-C time consolidation stand is based on the 1S-O open

time consolidation stand, which is fitted with a protective

cover. Existing time consolidation stands of type 1S-O can

be converted to type 1S-C by adding the protective cover.

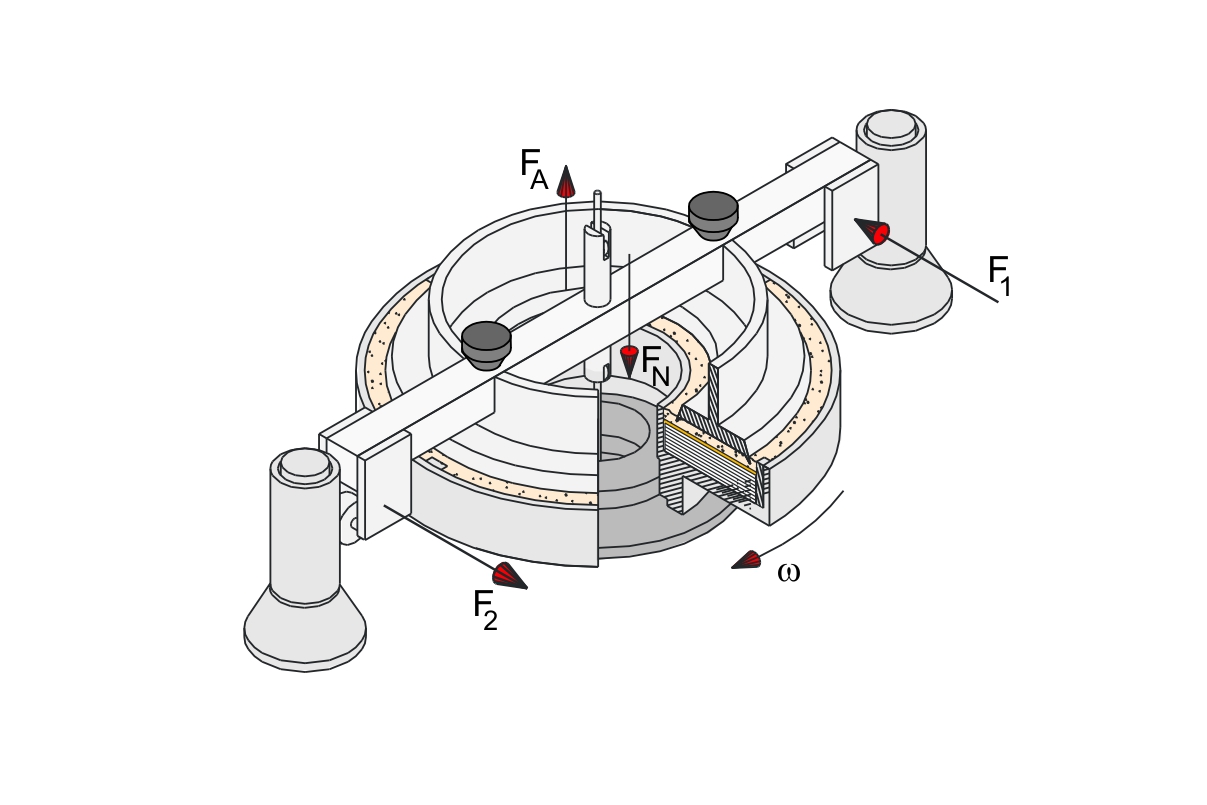

Wall friction cells

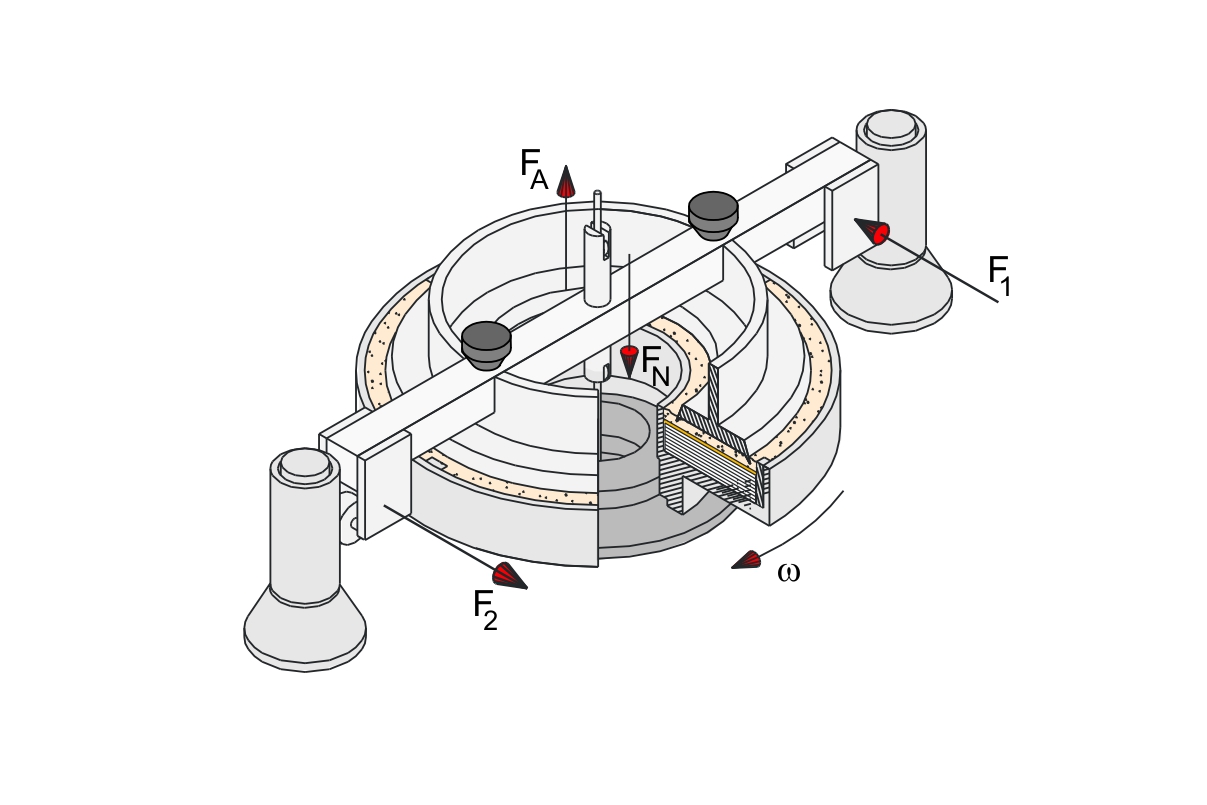

Wall

friction cells are required for the measurement of the wall

friction angle or coefficient of wall friction (friction

between a bulk solid and a wall material).

Wall

friction cells are required for the measurement of the wall

friction angle or coefficient of wall friction (friction

between a bulk solid and a wall material).

For

the test, an annular wall material specimen ("coupon") is

placed in the shear cell with the bulk solid specimen on

top, i.e., the bulk solid is located above the wall material

like on a hopper wall or a chute, which is absolutely

necessary in order to avoid underestimating the wall

friction angle in the case of segregating bulk solids. Wall

material coupons can be made by the customer according to

dimensions given in the tester's manual.

For

the test, an annular wall material specimen ("coupon") is

placed in the shear cell with the bulk solid specimen on

top, i.e., the bulk solid is located above the wall material

like on a hopper wall or a chute, which is absolutely

necessary in order to avoid underestimating the wall

friction angle in the case of segregating bulk solids. Wall

material coupons can be made by the customer according to

dimensions given in the tester's manual.

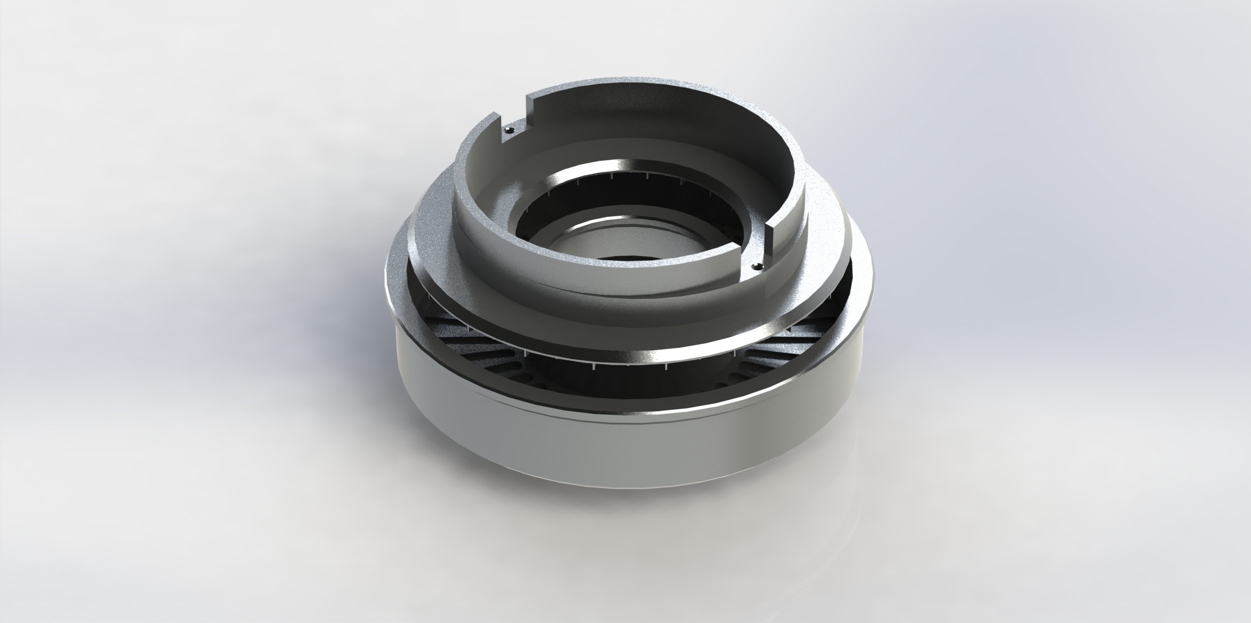

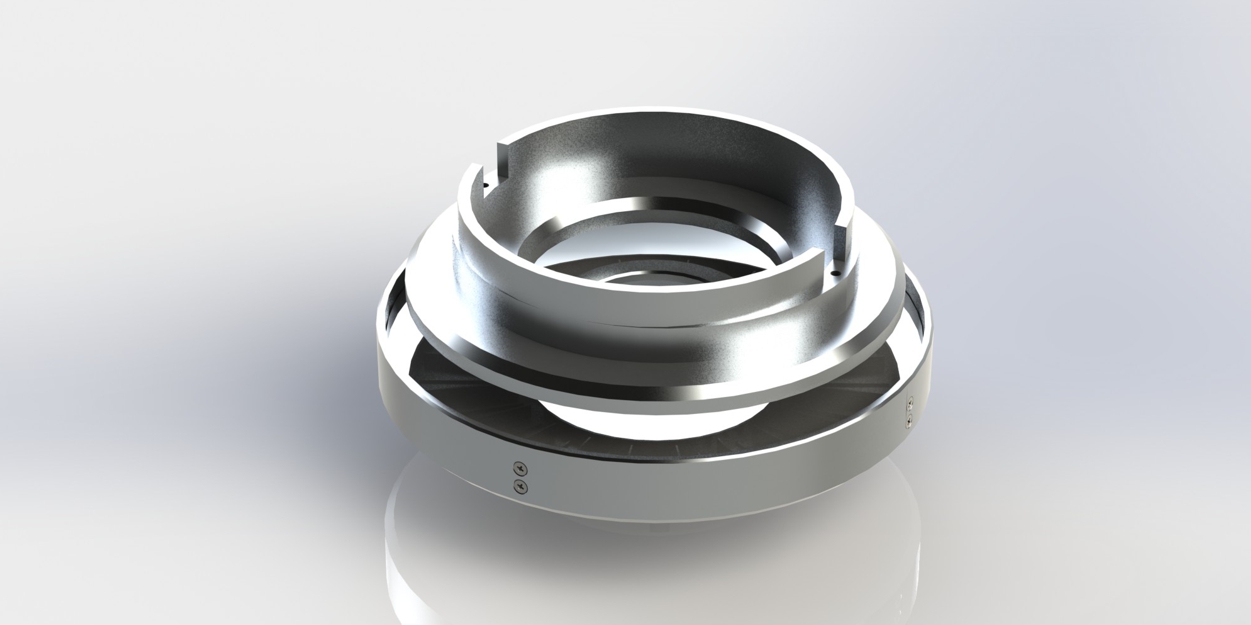

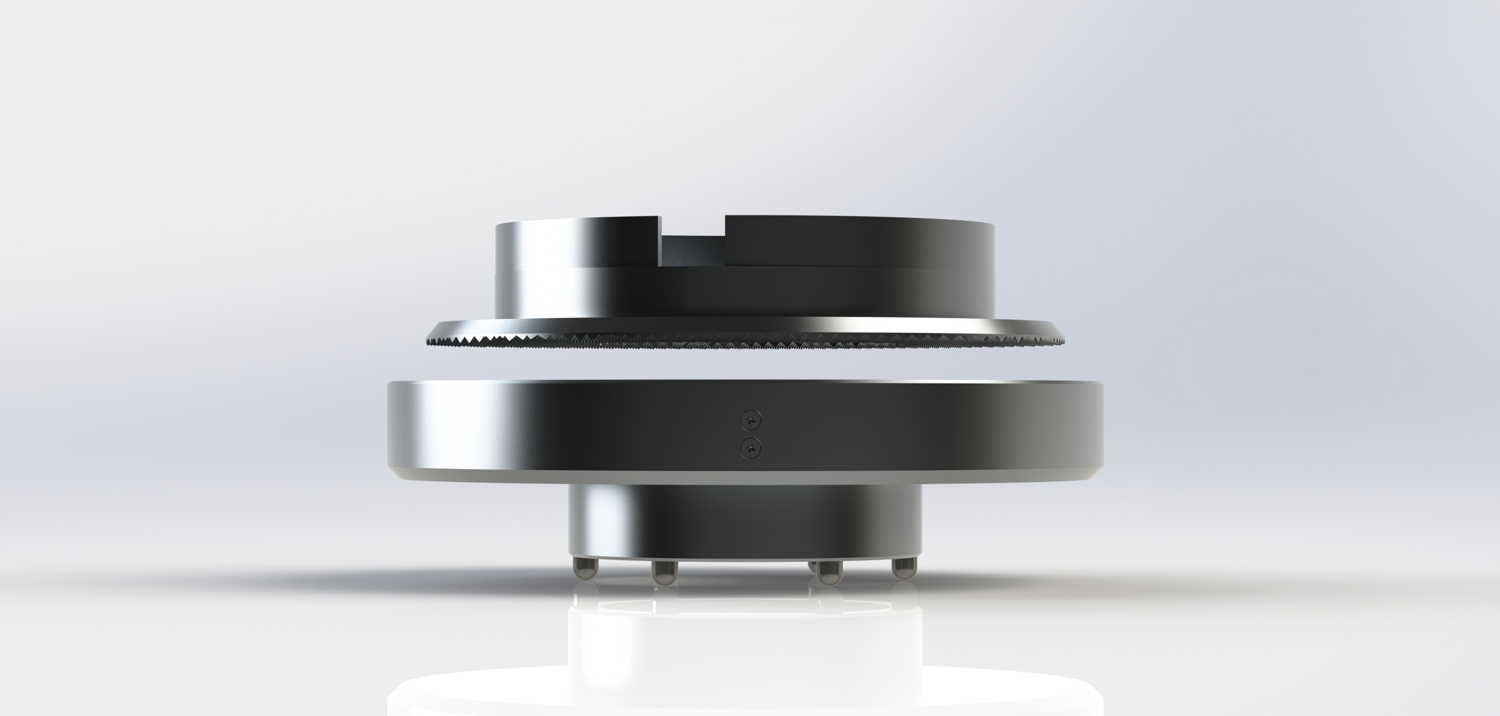

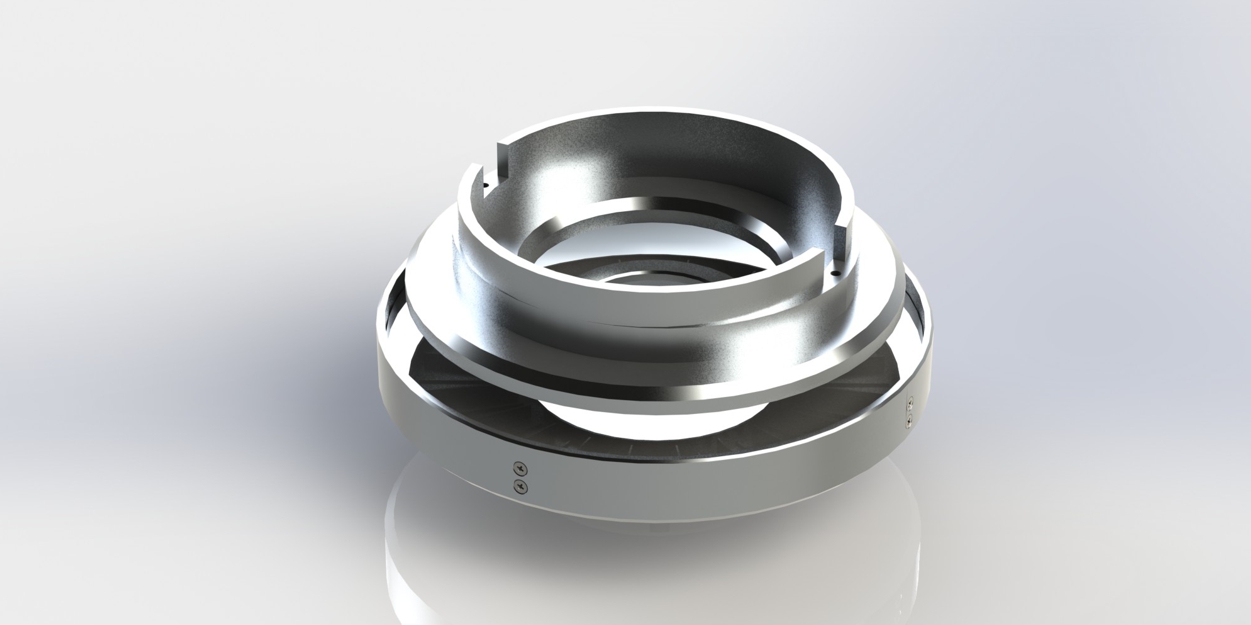

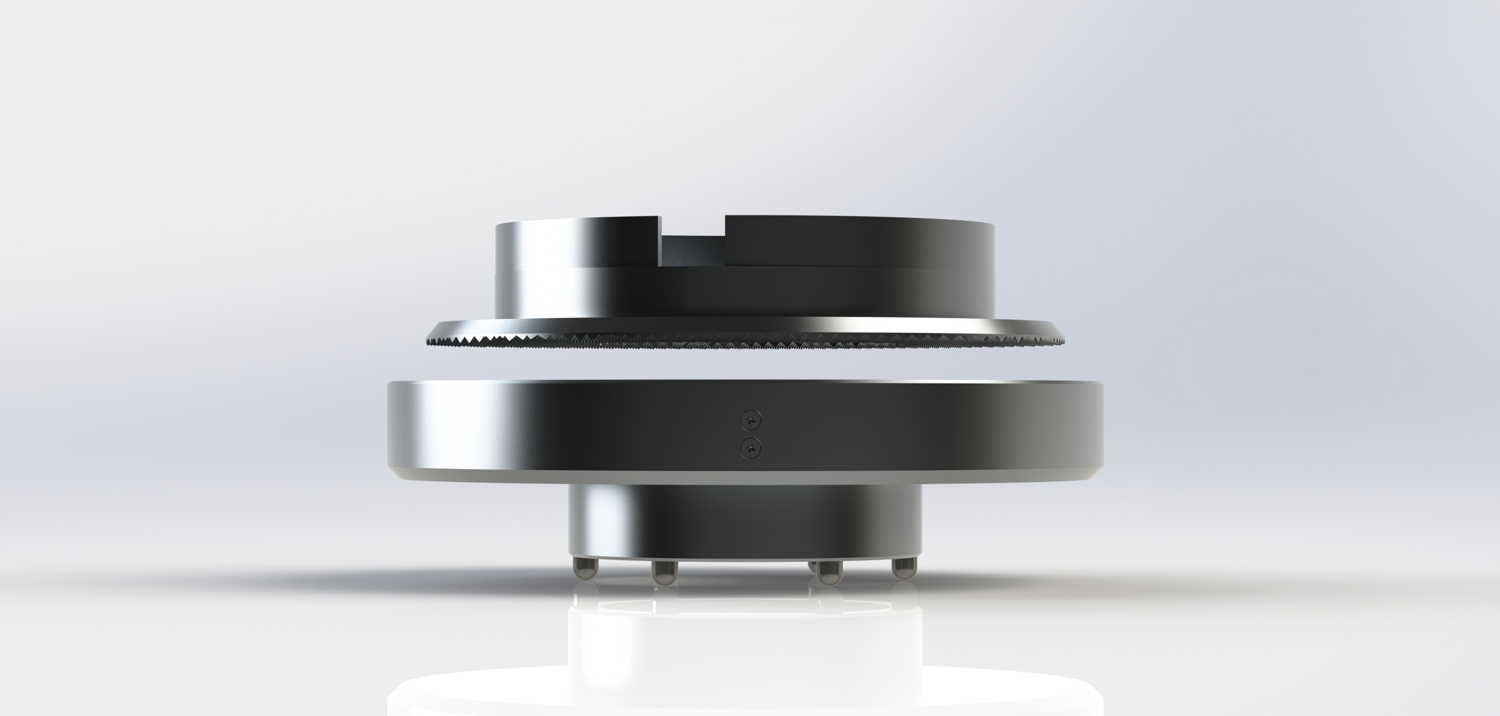

The picture above shows the current version of the wall

friction cell (shear cell type WM v2), which offers

advantages in terms of cleaning and weight. For fine-grained

bulk solids (powders), there is an optional rough lid

(picture below, principle as for the RST-XS.s ring shear

tester) instead of the normally used lid with vanes/pockets

which is preferable for coarse-grained bulk solids.

| Name |

Description |

| WM |

"Standard" wall friction cell, specimen volume

about 240 ml, outer diameter of the wall material

coupon about 215 mm.

Optionally with rough lid for optimization for fine

bulk solids |

| WS |

Wall friction cell with specimen volume of about

95 ml, outer diameter of the wall material

coupon about ca. 134 mm |